No products in the cart.

Introducing Anatol's exclusive SSE configuration!

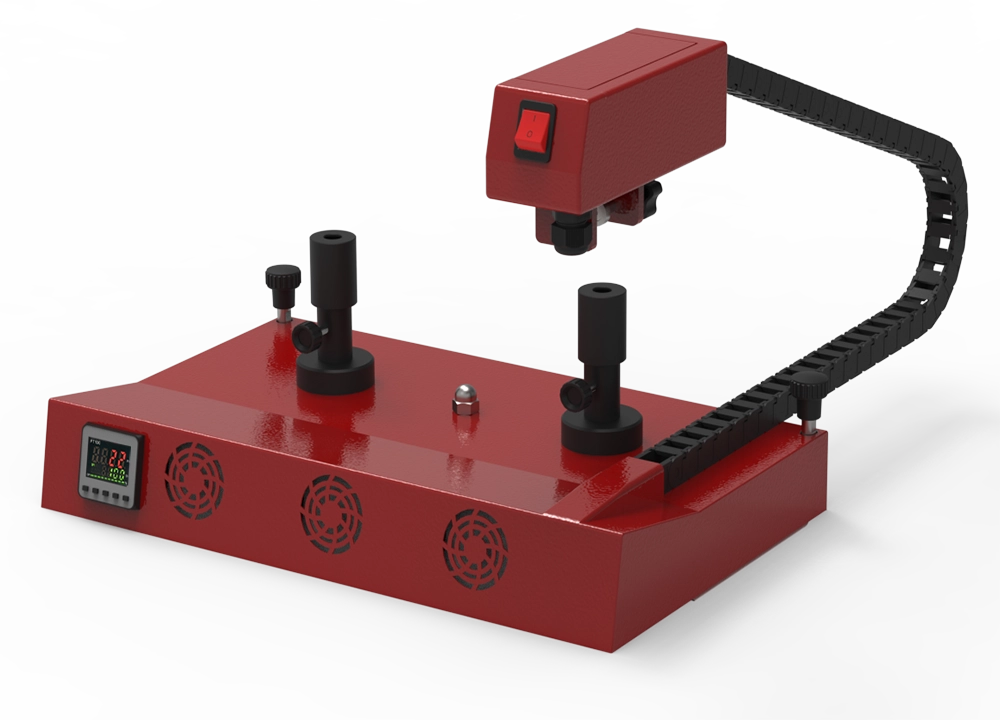

Want to take advantage of the benefits of electric screen printing, but our all-electric VOLT isn’t the right fit for you? The Vector Automatic Screen Printing machine is a step between a pneumatic-based press and Anatol VOLT. Vector utilizes electric technology combined with pneumatic free wheel (indexer locking/unlocking) and pneumatic up-and-down squeegee/flood bar “chop” movement. Anatol’s exclusive SSE configuration – servo lift, servo indexing and AC electric print heads – lets you print with maximum consistency and reliability. We’ve reduced air consumption rates to the lowest in the industry, saving you money and the hassle of pneumatic repairs. 90% fewer pneumatic components than competing screen printing presses, indicates that Vector requires less air, less maintenance, less downtime and less cost to operate.

The Anatol Vector is designed to be the most versatile automatic screen printing machine in the industry. Available in more sizes than any other auto and with all the features you expect from Anatol, the Vector lets you work the way you want – not the way your machine forces you to. The Vector is available in four different print areas up to 20″ x 28″: Vector S, Vector M, Vector L and Vector XL, in models from 4 to 18 colors.

Standard features

Print Heads

- AC electric-driven print heads enhance smoothness, speed and power

- Front and rear stroke adjustment

- Single-handed tool-less squeegee/flood bar locking for fast and easy loading and changeover

Registration

- True three-point micro-registration of screen (front-back, left-right, rotational movement)

- Compatible with Anatol’s ARME pre-registration system, as well as a number of other different pre-registration systems available on the market

- Easy Set Up mode shortens job setup times

Control Interface

- Aries 2 OS – User-friendly operation system

- 15’’ touchscreen with intuitive one-touch access to all job settings and machine functions for fast setup

- Rotating boom arm for easy access to each print head

- Easy access to operator’s manual

- Automatic software updates available via Wi-Fi

- Receive automatic email notifications with production statistics

- Connect the machine directly to Anatol Service with Presentation Mode

Functions

- Save all parameters of a stored job: off-contact, indexing speed, print head speed, number of strokes, flash cure time and temperature, ink colors

- Quickly copy the same print head settings to all heads

- Adjust flash cure temperature and intensity from the touchscreen

- Set pallet preheat temperature with smart flash

Heads Up Feature

- On machines with an odd number of print heads, this trait allows you to raise the last head on a hinge, to create dedicated loading and unloading stations.

- It’s like getting two machines in one. For example, a 10 station/9 color machine can become a 10 station/ 8 color machine when you need two operators to load and unload and aren’t using the last head, allowing you to work faster.

Pallet System

- Slide-style pallets allow for adjustments in print location

- Tool-free locking

- Precise four-point pallet leveling system

- 16’’x22’’ solid aluminum, low profile rubber-coated pallets standard, with a wide variety of custom pallets available separately

- Laser alignment system makes apparel alignment quick and easy

Skip Shirt & Smash Button

- Save time and supplies by preventing the press from printing on empty pallets

- Smash button halts printing in the event of a shirt being loaded improperly – more reliable than systems utilizing sensors

Indexing System

- Servo indexer allows for clockwise, counterclockwise and half indexing

- Smooth and quiet indexing at high speeds

- High – quality linear screw design

- Freewheel capabilities allow manual carousel rotation

Options

- Quick-release pallet system

- Foot pedal to control indexing

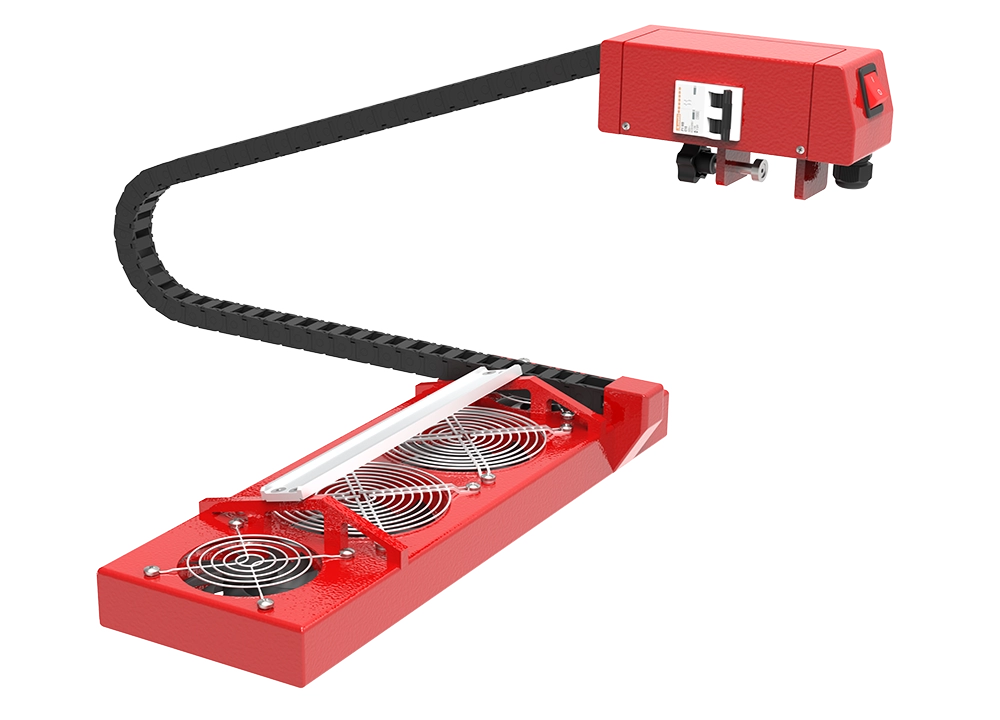

- Quartz flash cure units

- Special sizing available for doorways as small as 28’’

Safety System

- Safety bars, located between each print head, and on each side of the load and unload stations ensure safety during press set-up and operation

Central Off-Contact

- Digitally-controlled central off-contact with 38 settings up to 3/8’’, giving you the flexibility to print virtually any ink on any substrate with the touch of a button

Laser Alignment System

- Laser alignment system for quick and easy apparel alignment

- Four independently-adjustable straight red lasers

VECTOR Specifications

Vector S

| Stations Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Press Diameter | Stationary Arm or Boom Touchscreen Support | Electrical Requirements | Air Requirements @ 90 PSI |

|---|---|---|---|---|---|---|---|

| 06/04 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 9’4” | Boom | 1 ph 208/230v, 50/60 Hz, 13A 3 ph 208/230v, 50/60 Hz, 8A | 0.6 SCFM 17 l/min |

| 06/05 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 9’4” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.7 SCFM 21 l/min |

| 08/06 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 10’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min |

| 08/07 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 10’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min |

| 10/08 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 11’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min |

| 10/09 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 11’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min |

| 12/10 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 12’4″ | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.3 SCFM 38 l/min |

| 12/11 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 12’4″ | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.3 SCFM 38 l/min |

Vector M

| Stations Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Press Diameter | Stationary Arm or Boom Touchscreen Support | Electrical Requirements | Air Requirements @ 90 PSI |

|---|---|---|---|---|---|---|---|

| 06/04 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 9’8 | Boom | 1 ph 208/230v, 50/60 Hz, 13A 3 ph 208/230v, 50/60 Hz, 8A | 0.6 SCFM 17 l/min |

| 06/05 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 9’8” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.7 SCFM 21 l/min |

| 08/06 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 10’11” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min |

| 08/07 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 10’11” | Boom | 1 ph 208/230v, 50/60 Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min |

| 10/08 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 12’3″ | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min |

| 10/09 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 12’3″ | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min |

| 12/10 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 13’6” | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.5 SCFM 42 l/min |

| 12/11 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 13’6” | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.6 SCFM 46 l/min |

| 14/12 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 15’7″ | Boom | 3 ph 208/230v, 50/60 Hz, 16A | 1.8 SCFM 50 l/min |

Vector L

| Stations Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Press Diameter | Stationary Arm or Boom Touchscreen Support | Electrical Requirements | Air Requirements @ 90 PSI |

|---|---|---|---|---|---|---|---|

| 06/04 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 10’5” | Boom | 1 ph 208/230v, 50/60 Hz, 13A 3 ph 208/230v, 50/60 Hz, 8A | 0.6 SCFM 17 l/min |

| 06/05 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 10’5” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.7 SCFM 21 l/min |

| 08/06 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 12′ | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min |

| 08/07 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 12’ | Boom | 1 ph 208/230v, 50/60 Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min |

| 10/08 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 13’8” | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min |

| 10/09 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 13’8” | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min |

| 12/10 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 15’3” | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.5 SCFM 42 l/min |

| 12/11 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 15’3” | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.6 SCFM 46 l/min |

| 14/12 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 16’8” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 16A | 1.8 SCFM 50 l/min |

| 16/14 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 18’4″ | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 27A | 1.9 SCFM 54 l/min |

| 18/16 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 19’8” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 30A | 2.0 SCFM 58 l/min |

| 20/18 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 21’4” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 32A | 2.2 SCFM 63 l/min |

Vector XL

| Stations Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Press Diameter | Stationary Arm or Boom Touchscreen Support | Electrical Requirements | Air Requirements @ 90 PSI |

|---|---|---|---|---|---|---|---|

| 08/06 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 13’10” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min |

| 08/07 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 13’10” | Boom | 1 ph 208/230v, 50/60Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min |

| 10/08 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 15’ | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min |

| 10/09 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 15’ | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min |

| 12/10 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 16’6” | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.5 SCFM 42 l/min |

| 12/11 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 16’6” | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.6 SCFM 46 l/min |

| 14/12 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 18’ | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 16A | 1.8 SCFM 50 l/min |

| 16/14 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 19’6” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 27A | 1.9 SCFM 54 l/min |

| 18/16 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 20’10” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 30A | 2.0 SCFM 58 l/min |

| 20/18 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 22’8” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 32A | 2.2 SCFM 63 l/min |

Premium service that will exceed your expectations

Customer Service and Support are a way of life at Anatol Equipment. We strive to improve our service to keep your equipment running like the day you had it installed. This is our commitment to every customer. Two-year limited warranty.

Anatol Support Contacts

We are always ready to help!

847-582-1825Warranty Registration

Please complete all form fields. By submitting this form you agree to all Warranty Terms & Conditions. You must complete a form for EACH Anatol machine you wish to register.

Questions & Answers

Need help? Have Questions? Want answers?

We’ve compiled a list of commonly asked questions our customers ask most frequently. You’ll find your answers here.