No products in the cart.

en

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Phone: +1 847-367-9760

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

The best screen printing results always begin with well-executed pre-press. It’s easy to think of your screen printing press as the backbone of your operation. But remember, a press can only deliver quality prints if it’s printing through quality screens. Your screens deserve as much attention as any other part of your setup, because no […]

Read more

When we talk screen printing, it’s easy to picture full-size, multicolor designs printed across the front or back of a t-shirt. But that’s not the only place you can show off your work! Whether you’ve got your own clothing brand or you’re printing shirts for a customer’s label, creating custom tags can be a cool way to add a professional look to your products.

Read more

Screen printing makes an excellent hobby. If you’re creatively inclined, making a design and reproducing it on a shirt can be a very satisfying feeling. It’s even better when you share your work with friends and family! After awhile, you may find yourself wanting to spread your designs to an even wider audience.

Read more

In the world of screen printing, a hot debate surrounds technique: Should you push or pull your squeegees on your manual screen printing machine? Some printers will argue that the best technique for manual screen printing is to pull your squeegee down the screen toward you in the traditional screen printing manner, while others will argue that pushing the squeegee away from your body is best.

Read more

Whether it’s your first screen printing machine or you’re looking to add another press to your setup, it can be tempting to go the used route. Screen printing presses – especially automatic machines – are big investments and every dollar counts for your business. You can save a bundle by opting for a used press over a new model, but there is some risk involved. If you’re set on purchasing pre-owned equipment, you have to do your research to make sure you’re getting a solid machine.

Read more

Nearly all printers begin with simple, color-blocked prints, laying down one to three colors at a time. While there’s certainly plenty of money to be made, and plenty of designs to be made, by printing spot colors, many screen printers look to advance their skills and try new techniques.

Read more

If you’re reading this, it’s time to move up to a larger manual screen printing press, add one to your screen printing arsenal, or replace an older, worn out model.

Read more

When shopping for a screen printing press, there are many variables you’ll have to take into account. One of the most important decisions to make is how many colors and stations you want.

Read more

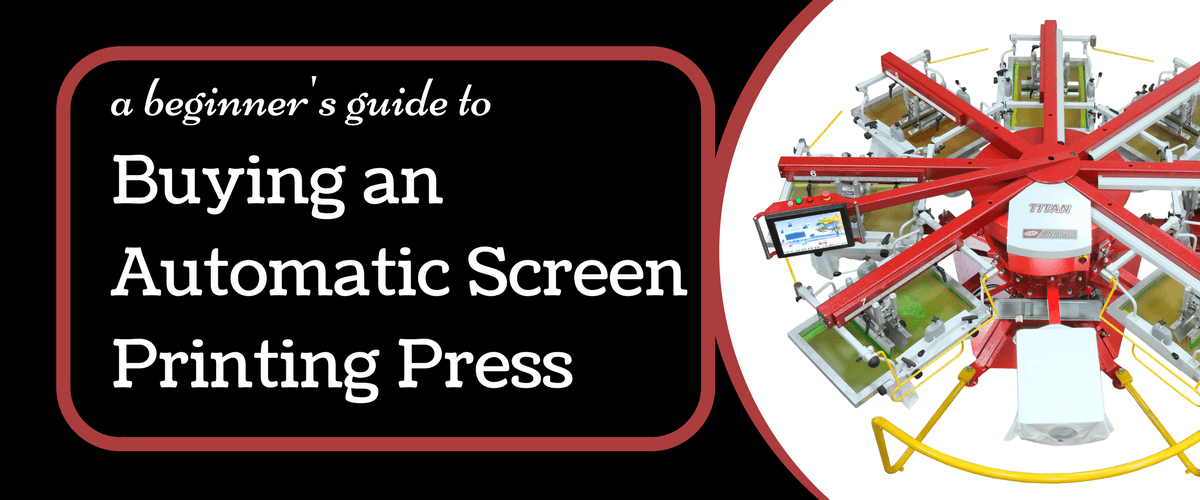

Is your screen printing shop ready to upgrade to an automatic screen printing press? If you’re consistently struggling to keep up with customer demand on your current manual setup, or if you’ve hit the point where you feel you need to increase your staffing, it’s probably time to start seriously considering an automatic press.

Read more

An automatic screen printing press is an exciting addition to any shop’s production floor. Automatic presses speed up production time, so press runs that used to take a day now only take hours. However, screen printing shops that adopt automatics shouldn’t be too fast to retire their manual screen printing presses.

Read more

There’s an old adage: “Keep your eye upon the doughnut and not upon the hole”. Of course, with screen printing it’s sort of reversed, as it’s most important to keep your eye on the holes in your screen mesh.

Read more

When it comes to screen frames, there are loyalists in all camps. Some screen printers love the old-school feel, low price and sustainability of wood. Others rely on the light, sturdy technology of aluminum frames, and still others swear by the control and print crispness that come with retensionable screens.

Read moreYour message was successfully sent!