No products in the cart.

en

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Phone: +1 847-367-9760

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

The biggest reason to use a flash is to cure an underbase, and not all jobs require one. If you’re printing a multicolor design on light colored garments, it’s often possible to set up your artwork to eliminate flash curing completely. This is called wet-on-wet screen printing, and it can help you get more work out in less time.

The reason this technique is called wet-on-wet is pretty self-explanatory – it lets you print your layers of ink without curing them between colors, so the previous layer is still wet when the next is put down. Your artwork determines whether you can print wet-on-wet or not. There are a few ways multicolor artwork might be set up: with individual colors overlapping, edge to edge or not touching at all. If your colors are laid out with no overlap, either edge to edge (“butt registered”) or not touching, you should be able to print wet-on-wet. Wet-on-wet screen printing is most appropriate on white or light colored shirts because they don’t require an underbase to produce vibrant prints like you need on dark shirts.

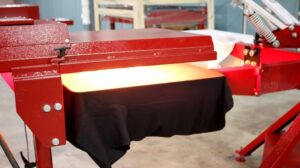

Sometimes a flash cure is just plain necessary – on dark shirts, an underbase will require flashing before more ink layers can be added on top. You’ll also need a flash for most specialty inks, like glitter or puff ink. These special effects are usually not designed to be printed wet-on-wet and can cause issues in your final print if they’re not flashed. It’s a good idea to apply specialty inks at or near the end of print sequence and flash them, rather than attempt to print subsequent layers on top.

Because screens pick up ink from previous layers when printing wet-on-wet, some colors can be diluted and not print as brightly as you’d like. If you can’t fix the issue by changing that color’s position in the printing sequence (printing it later in the order will keep it brighter), you might need a flash to keep that layer vibrant. If you’re flash curing between colors, it’s a good idea to let your shirts cool down before you add the next layer of ink.

Printing wet-on-wet can be done with either plastisol or water-based ink, but some inks are more appropriate than others for this technique. You’ll want to use the thinnest ink deposit you can – thick layers can cause screens to stick to the ink and smear colors. You’ll also want to keep your layers thin because over the course of a print run your screens will pick up wet ink from previous layers. This is normal and usually doesn’t affect the quality of the print, but too much ink buildup can cause blurry or smeared prints or even block parts of the stencil entirely, ruining your design. If you notice ink buildup having a negative effect on your print quality, take a second to clean the substrate side of your screens.

To make sure you’re laying down the thinnest layer of ink possible without compromising the quality of the print, use screens with a high mesh count (200+) and high tension. Your ink manufacturer may be able to recommend inks specially designed for printing wet-on-wet, or reducers you can add to your inks to ensure a thin deposit. Experiment with your print parameters to get the best results. Many variables determine the optimal settings, but in general it’s a good idea to use light squeegee pressure and a small off-contact distance. Like any printing technique, practice makes perfect! Try to print some test shirts before you begin the actual print run – this way you’ll know what to expect during production and you can make any necessary adjustments.

The seconds it takes to flash cure a layer of ink may not seem like much, but they add up over a long print run. With wet-on-wet screen printing you can work faster and more efficiently, cut down on wasted time and get your customers their products as quickly as possible.

Looking for more ways to speed up your screen printing production? Check out our blog post:

How to Keep Up with Your Screen Printing Shop’s Customer Demand

Or give us a call and let’s talk screen printing!

Your message was successfully sent!

Leave a Comment

Thank you sooo much for breaking this down. I been stressed all week, trying to learn how to print on dark colors cause sublimation don’t work on them. So I thought to do print and cut and I am just exhausted at this point. It’s extremely hard and after reading your article and others, sadly I am going to cough up some money for a cheap screen printing machine.