Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

When your prints aren’t turning out quite as they should, your screen tension may be to blame! Not only can improperly tensioned screens reduce your print quality, they can also lessen your shop’s efficiency. Fortunately, there are some steps you can take to make sure your screens are set up for optimum performance.

Put yourself in this situation: You’re beginning a print run when you start to notice your prints are coming out blurry, smeared, or otherwise flawed. The suspects that’ll probably jump to mind first are your artwork and your screen printing press. As you investigate the root of the problem, you find your artwork was set up perfectly and your press appears to be operating normally. What’s to blame for the misprints? Your screen tension may be a less obvious culprit, but it can cause big problems.

Screen tension is how tightly your mesh is stretched in the frame, measured in Newtons per square centimeter (N/cm2). Over time, screens lose tension as repeated strokes of the squeegee strain and distort the mesh, making it more difficult for the mesh to return to its original shape. Screens with improper tension can cause a whole host of issues:

How do you tell if your screens have proper tension? You need to know:

Proper tension is typically between 25 and 35 N/cm2, but you can usually get away with a minimum of 15 N/cm2. Anything less than that and it may start to affect your print quality. How do you find these measurements?

In order to measure your screen tension, you’ll need a device called a tension meter. It rests on the print side of the screen and detects the amount the mesh gives under its weight. When you measure, make sure your screen is on a flat, level surface. Don’t just measure in one place – check all over the screen to make sure the tension is uniform for consistent results. Make sure you measure your tension in two directions – from top to bottom of your screens (warp), and from one side of the screen to the other (weft).

If you notice your screen tension is less than 15 N/cm2, how can you fix it? It’s possible to adjust the tension of your screens yourself if you have the right tools. A screen stretcher is a device that uses either manually-operated or pneumatic clamps to bring your mesh back up to proper tension. If you don’t want to add additional equipment, you can make the job even easier by using retensionable (or roller) frames. If you don’t want to do it yourself, there are places you can send your screens to have them retensioned.

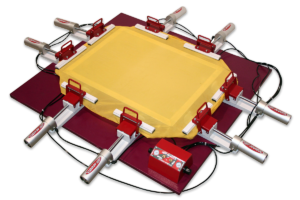

Anatol’s pneumatic screen stretcher takes the work

out of bringing your screens back up to proper tension.

Keep in mind that your screen tension depends in part on the type of frames you’re using. Wooden frames can lose tension over time when exposed to moisture or temperature changes. The adhesive used to hold the mesh to metal frames can degrade over time, causing improper tension. Even roller frames may lose their grip on the mesh over time, so check them regularly to make sure they’re holding proper tension and adjust as necessary.

When you’re printing, there are some additional steps you can take to maintain proper screen tension. It’s a good idea to use the least amount of off-contact possible and make sure your screens and pallets are level and parallel. This avoids the need to use excessive squeegee pressure, reducing the stress on your screens and allowing your squeegee to travel faster, boosting your print speed, productivity and efficiency.

One last thing to consider – too high of screen tension can also be a problem! If your mesh is stretched too tightly, your screens will be more susceptible to damage during printing and potentially more difficult to print through if you’re using a manual press.

Looking for some more tips on how to keep your screen prints looking great? Check out our blog post:

7 Screen Printing Practices That Will Improve Your Finished Product

Your message was successfully sent!