No products in the cart.

en

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Phone: +1 847-367-9760

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Learn how to reduce plastisol ink use in screen printing with eco-friendly alternatives like water-based, discharge, and soy-based inks. Optimize your setup with Anatol’s advanced presses to minimize waste while maintaining quality. Discover sustainable practices for vibrant, environmentally conscious prints.

Read more

DTF vs. HTV: Which textile printing method suits your needs? Compare design complexity, fabric versatility, durability, and cost. DTF excels in vibrant, detailed prints for bulk orders, while HTV offers simplicity and unique finishes for small projects. Choose the best for your business or hobby!

Read more

Discover all the essential supplies needed for successful heat press projects, including high-quality heat press machines, heat transfer vinyl (HTV), transfer paper, cutting tools, blank apparel, protective accessories, and design software. This comprehensive guide helps you achieve professional, vibrant custom designs right from the comfort of your home.

Read more

Learn how to use a heat transfer press with our beginner’s guide! Create vibrant, long-lasting designs on T-shirts, hats, and more using Anatol’s user-friendly machines. Follow our step-by-step process to achieve professional results, avoid common mistakes, and start your custom apparel journey today!

Read more

Discover the inspiring journey of Six12 Printing, a Dallas-based screen printing business driven by family, faith, and grit. From humble beginnings in a garage to mastering a 2,500-shirt order, Jon and Joe transformed their passion into a thriving enterprise with Anatol equipment. Now, they’re mentoring aspiring printers and expanding with DTG printing and an eBook on ink mixing. Read their full story of perseverance and community impact!

Read more

The textile printing industry is constantly evolving. To stay competitive, businesses are always looking for ways to boost productivity, expand their services, and work more efficiently. Some print shops focus only on digital printing, while others rely solely on screen printing. Each method has its own strengths and ideal use cases. Today, many forward-thinking shops […]

Read more

We get it – running a screen printing shop is a labor of love, but it comes with challenges. Slow seasons and tight budgets can test your passion. At Anatol Equipment, we’ve worked with screen printers from small startups to large shops, and here’s the good news: you can grow without a large budget. With […]

Read more

The printing industry is thriving, driven by innovation and creativity. Screen printing trends in 2025, including specialty inks and eco-friendly textile printing, help printers produce distinctive clothing.Today, we are going to look into some of the trends that are influencing not only the day-to-day process for printers, but also the future of the industry as […]

Read more

Selecting the right screen printing ink is essential to get bright, long-lasting, and professional results in your projects. At Anatol, we understand that ink selection is as important as selecting the right screen printing press or mesh. The type of ink you use affects print quality, durability, feel, and eco-friendliness. This guide covers the best […]

Read more

Traditional pneumatic screen printing presses rely on air compressors, which can cause issues like air leaks, moisture buildup, and high maintenance costs. The Anatol VOLT, the industry’s first all-electric screen printing machine, transforms your print shop by eliminating compressed air. It offers unmatched screen printing energy efficiency, precision, and ease of use. This article highlights […]

Read more

Air compressors and pneumatic systems are essential for many screen printing shops. They power automatic presses and other equipment to keep production efficient. However, issues such as low air pressure, moisture buildup, and air leaks can interrupt your work, reduce print quality, and increase maintenance costs. In this guide, we will review six common air […]

Read more

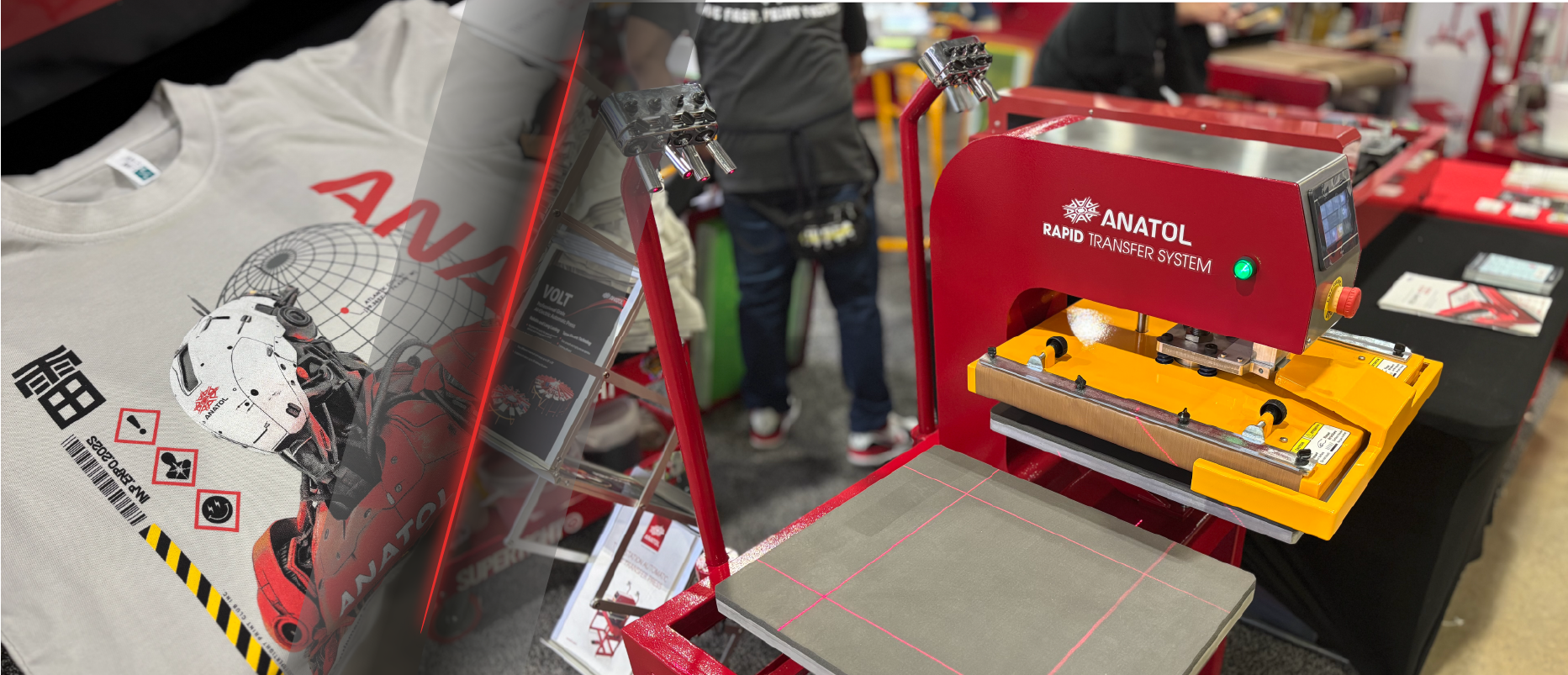

The Decorated Apparel Expo (DAX) 2025 in Nashville was a significant event for Anatol. It provided a unique opportunity to connect with screen printing professionals in an intimate, focused setting. The event took place at the Farm Bureau Exposition Center on May 9–10. It focused on education, hands-on demonstrations, and meaningful one-on-one interactions. Anatol’s Featured […]

Read moreYour message was successfully sent!