Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

There are four basic types of pallet adhesive; the one you choose to use will be dictated by your screen printing project and your personal preference.

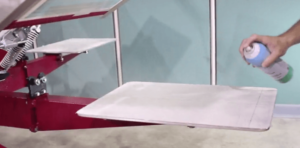

The most commonly used type of pallet adhesive is spray adhesive. These come in aerosol cans and are sprayed directly onto the platens. They’re easy to use and effective, and they come in several varieties so you can choose the ones that work best for your project. Heat-resistant spray adhesive is needed for jobs that will be flash cured, and web spray adhesives are used for heavier substrates, such as fleeces.

If there’s one downside to spray adhesives, it’s that the spray can fall onto nearby materials, get into your screen printing press parts or cause a buildup of adhesive on your press platens. It’s important to be careful to watch your spray and to keep any tools that could be damaged by the adhesive, such as screens, out of the way.

Water-based adhesives are budget friendly, easy to use and easy to clean up. The adhesive is applied to the platen with a brush, roller or squeegee. If it starts to lose some of its tackiness, the adhesive can be reactivated with a wet sponge. Water-based adhesive can be cleaned up with alcohol.

Water-based adhesives won’t work with some heavier garments.

While bulk adhesives can be used in any screen printing shop, they’re popular with shops that do a high volume of prints. The adhesive comes in five-gallon buckets and can be applied with a brush or plastic spatula, or it can be sprayed on using a compression system or sprayers sold by the adhesive manufacturers.

Bulk adhesive can leave residue or affect nearby materials or screen printing press parts if they’re applied with a sprayer, and care must be taken not to get the adhesive on your press parts or materials that might be laying nearby.

Sheet adhesive works like double-sided tape to stick to your platen and hold your substrate in place. Sheet adhesives come either in rolls or in pre-cut sheets that are ready to apply to your platens. Sheet adhesive is usually used in small shops or for small press runs because it doesn’t hold its tackiness for very long.

Sheet adhesives also can cause problems if they’re left in place for too long; they can stick to your platen and become difficult to remove, and they can leave a residue behind.

Ultimately, the pallet adhesive you use will depend on which type you find works best on your press and in your shop. Try the different types of adhesives to find your preference, and you may find that you stock a few different types so you can customize your adhesive to your press run.

Looking for more tips about setting up your print jobs for the best possible results? Keep checking out our blog, or get in touch – we’re always happy to talk screen printing!

Your message was successfully sent!