Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

With Section 179 of the IRS tax code, you can deduct the total cost of qualified equipment you buy in 2025, up to $3,130,000 in total purchases. You can also take advantage of 40% bonus depreciation on both new and used equipment purchased in 2025. Act now before the year ends.

Read more

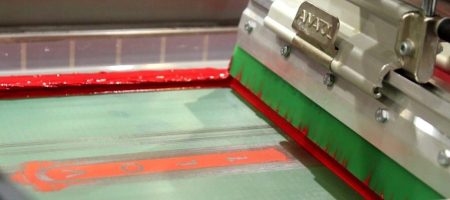

Flashing is a critical step in the screen printing process, especially when working with multi-color designs or specialty inks. It refers to the process of briefly curing the ink between print strokes using a flash dryer.

Read more

Screen printing, from ancient Chinese stencils to modern automated systems, blends tradition with innovation, creating vibrant, durable designs on various surfaces

Read more

High density printing is a unique screen printing technique that creates bold, raised, and vibrant designs with a premium look. By applying thick layers of ink, it delivers long-lasting colors, tactile appeal, and eye-catching graphics. Discover how this method helps brands and designers produce unforgettable apparel with maximum visual impact.

Read more

Discover how to boost your screen printing speed without sacrificing quality. From choosing the right equipment and inks to streamlining setup, curing, and team training, these practical tips help you achieve faster turnaround times while keeping prints sharp and professional.

Read more

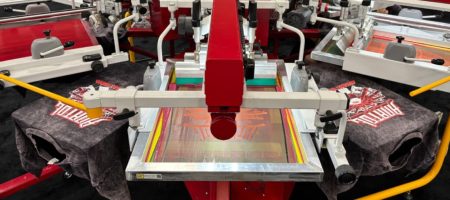

Anatol Automatic Screen Printing Presses: Save time, Energy, and Money For most screen printing shop owners, producing quality prints is the easy part. The real challenge is managing day-to-day operations, meeting business goals, and ensuring your company continues to grow. If your business feels stagnant, it might be time to take a hard look at […]

Read more

Conveyor dryers are essential for high-quality screen printing, but common mistakes can hurt results. This article covers four key issues—wrong temperature, incorrect belt speed, poor maintenance, and overloading—and offers practical solutions. Learn how Anatol’s conveyor dryers help ensure consistent curing and improved efficiency.

Read more

Keep your screen printing machine in top shape with our maintenance guide. Learn daily, weekly, and monthly tasks to ensure high-quality prints and avoid downtime. Discover when to call Anatol’s professionals for expert repairs and maximize your equipment’s lifespan.

Read more

Pricing is the backbone of a successful screen printing business. This guide helps you calculate true costs, set minimum orders, apply volume discounts, and build a sustainable, profitable pricing strategy.

Read more

Many small shops start with manual screen printing, but growth brings limits. Explore 7 clear signs it’s time to upgrade to automatic presses. With Anatol Equipment’s support, streamline production, improve quality, and increase profits while keeping your shop competitive and ready for the future.

Read more

Discover how Kyle and Kim Blumenberg transformed West County Tees & Embroidery into a thriving custom merchandise business in Chesterfield, Missouri, with the Anatol VOLT automatic press. From humble beginnings with a manual press to serving schools and sports teams, their story highlights the power of quality, community, and cutting-edge equipment. Read more about their journey and the impact of the VOLT!

Read more

Master squeegee pressure for flawless screen printing. This guide covers setting optimal pressure, avoiding common mistakes, and using Anatol’s advanced equipment for vibrant, sharp prints. Learn expert tips, adjust for inks and substrates, and boost efficiency with precise, digital controls.

Read moreYour message was successfully sent!