Big Forge - In-line Heat Press

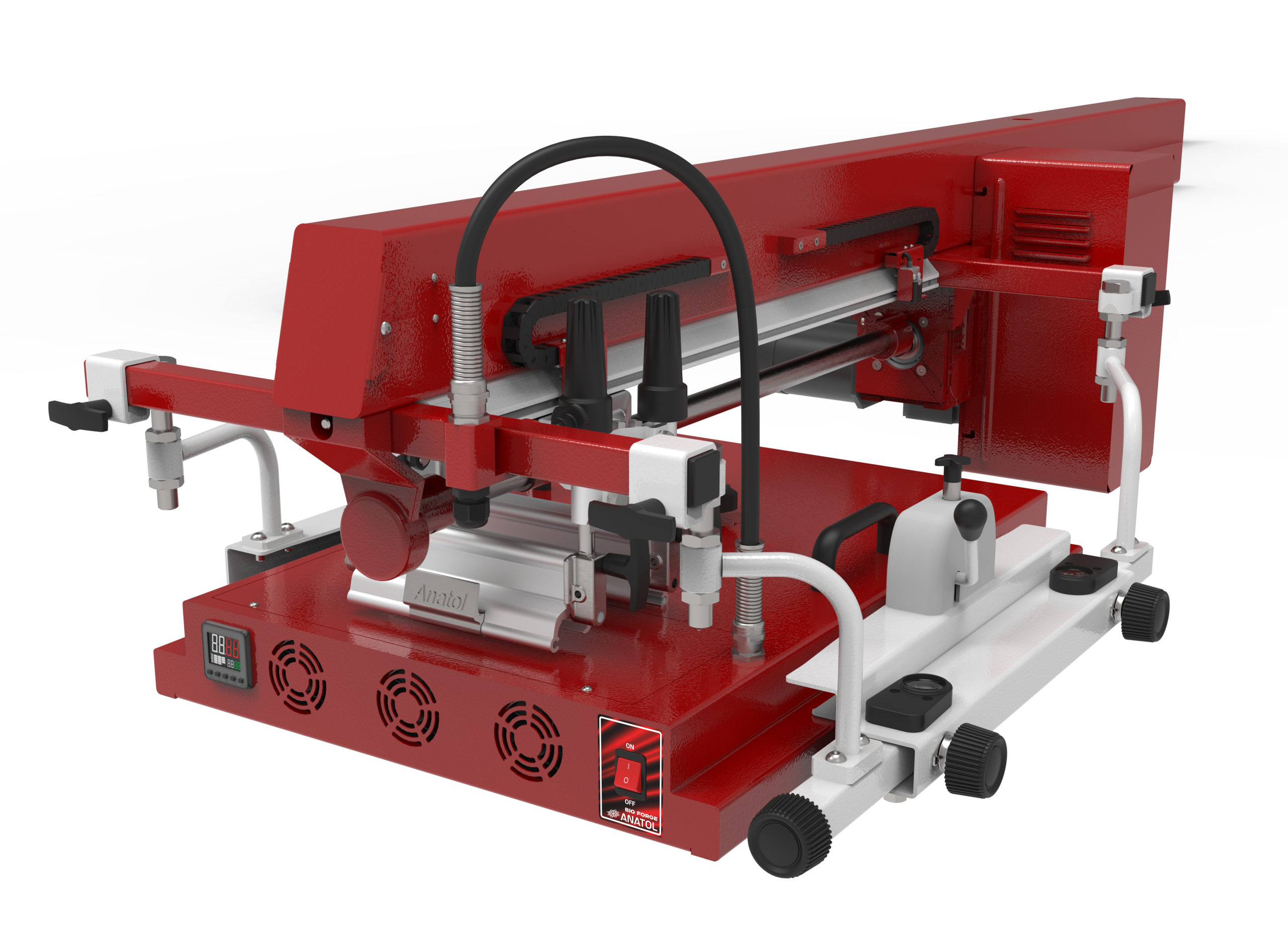

Transform your screen printing process with Anatol’s Big Forge in-line heat press. This innovative tool improves print quality, speeds up production, and unlocks new creative opportunities. Anatol designed the Big Forge to integrate seamlessly with their VOLT, VECTOR, and TITAN automatic screen printing presses. It combines the functions of a flash dryer, heat press, and transfer device—perfect for high-volume professional production.

Why Choose the Big Forge In-Line Heat Press?

The Big Forge is more than just a heat press—it’s an innovative tool that streamlines your screen printing workflow. It flattens fibers, levels ink layers, and reduces fibrillation to create a smooth, solid underbase. This foundation is key to achieving vibrant, high-quality prints, especially on dark garments.

The Big Forge handles a wide range of tasks with ease. You get consistent, high-quality results every time. This applies when you apply foil, cure discharge inks, or add materials such as rhinestones, numbers, vinyl, or Cad-Cut designs.

Key Features of the Big Forge Heat Press

- Versatile Applications: The Big Forge supports flash-curing of underbases and final curing of plastisol ink. It also allows one-step application of foil, rhinestones, numbers, vinyl, twill patches, and heat transfers.

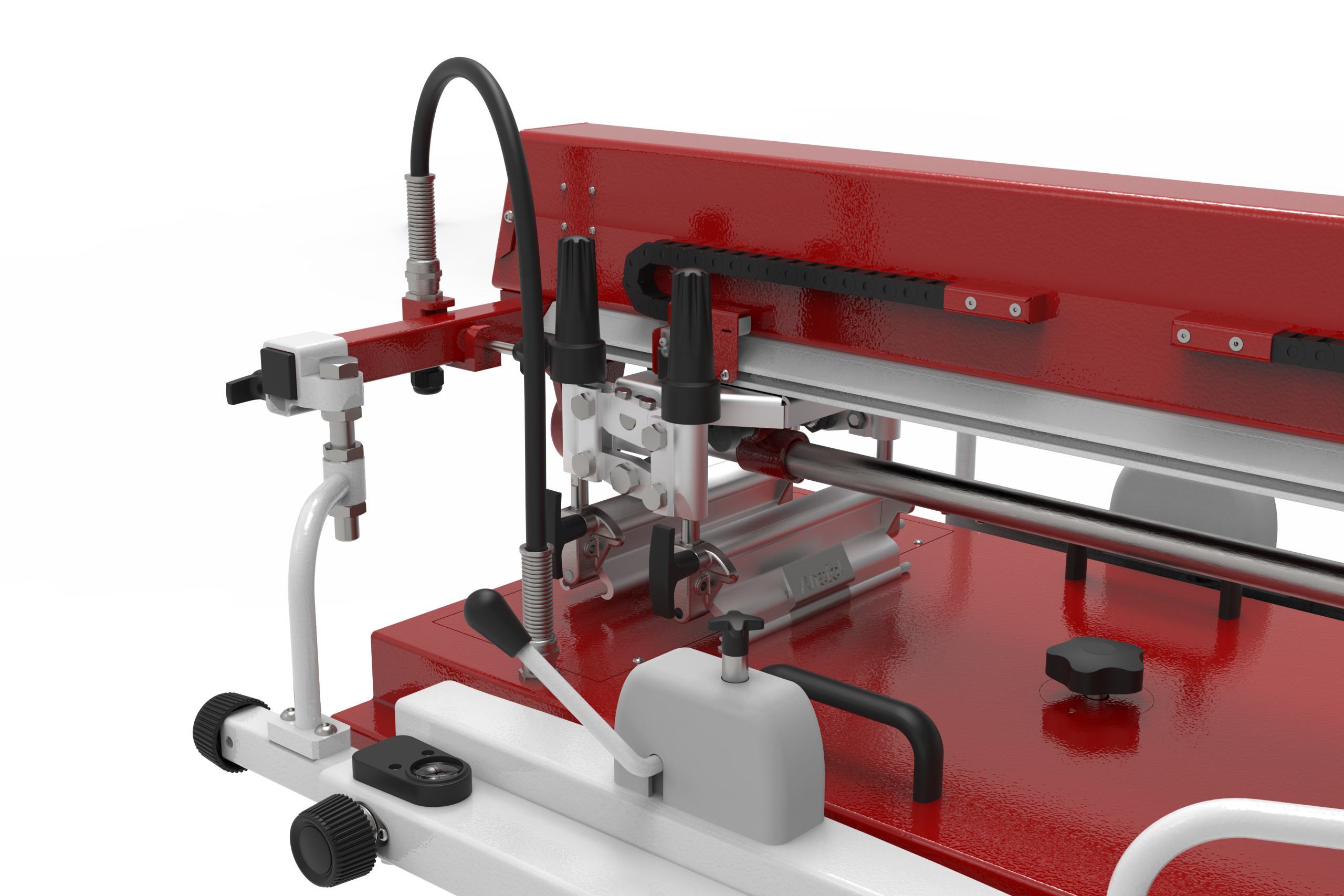

- Seamless Integration: It easily mounts in the screen holders of Anatol VOLT, VECTOR, and TITAN presses. Compatible print areas include S (15”x16”) and M (16”x18”).

- Uniform Heat and Pressure: Its unique design spreads heat evenly across a 16”x18” area. It can reach temperatures up to 392°F (200°C).

- User-Friendly Operation: Features digital temperature control for precise adjustments and automatic temperature maintenance.

- High Efficiency: Reduces processing time, lowers costs, and automates key steps in the printing process.

- Robust Build: Weighs approximately 27 kg, powered by 230V / 3.6 kW, built for durability in demanding production environments.

Benefits for Your Screen Printing Business

The Big Forge in-line heat press is designed to elevate your production capabilities. By compressing fibers and creating a smooth ink base, it improves image sharpness and color brightness. Its multi-functional design also means you need fewer machines. From hot foil stamping to curing discharge inks, the Big Forge simplifies complex tasks, saving time and increasing profits. Its main advantages:

- Enhanced print quality with reduced fibrillation and smoother ink layers.

- Streamlined workflow with integrated flash-curing and final curing capabilities.

- Cost-effective solution for applying specialty materials like foil and rhinestones.

- Easy installation and independent operation for maximum flexibility.

Elevate Your Screen Printing with Anatol’s Big Forge

Ready to take your screen printing to the next level? The Big Forge in-line heat press combines flexibility, efficiency, and premium quality. It’s an essential tool for any professional print shop. Contact Anatol today to learn how the Big Forge can transform your production process.

| Heating Surface Area | Maximum Temperature |

Weight | Overall Dimensions | Electrical Requirements |

|---|---|---|---|---|

| 16″ x 18″ 47.4cm x 41cm |

392 F 200 C |

73lbs 33kg |

24.5″ x 11.7″ x 17.7″ 62.4cm x 29.6cm x 45cm |

1 ph 230v, 50/60Hz, 3.6kW, 9.1A/Ph |

Premium service that will exceed your expectations

Customer Service and Support are a way of life at Anatol Equipment. We strive to improve our service to keep your equipment running like the day you had it installed. This is our commitment to every customer. Two-year limited warranty.

Anatol Support Contacts

We are always ready to help!

847-582-1825Where to buy

Anatol’s direct sales team is always ready to share their experience and expertise to help you find the right screen printing machine for your business’s needs.

Where to buyQuestions & Answers

Need help? Have Questions? Want answers?

We’ve compiled a list of commonly asked questions our customers ask most frequently. You’ll find your answers here.