Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Halftone printing can open up new opportunities for finely detailed, photorealistic screen prints. It’s true that screen printing halftones can be a challenge, but taking time to learn to print halftones right can have you creating prints that wow your customers and help you attract new business.

As with most screen printing techniques, halftone printing involves carefully following the steps and putting some quality control in place. To print great halftone images, you start with quality artwork, formatted properly for screen printing; expose a solid stencil on the right type of screen; and employ printing techniques that lay down precise dots of ink to create your halftone image.

You know that to screen print great images, you need to start with great artwork. That’s especially true when printing halftones. Halftone printing creates detailed images. If your original image isn’t high enough resolution, the edges of your halftone dots won’t be clear and precise.

When printing halftone images, most programs will default to print settings made for paper. Before printing your film positives, you’ll need to adjust your print settings to format your image for screen printing halftones. Most printers prefer an elliptical dot shape and choose to print between 45 lines per inch (LPI), which is suitable for most halftone images, and 65 lines per inch for photorealistic images. You’ll also need to change the output angle. While many screen printers debate the proper angle, a good starting point for those just beginning to print halftones is 25 degrees.

There are many different ways to create a halftone image, but the principle

remains the same – taking a detailed image and breaking it down to fine dots.

Finally, you’ll have to set the color range of your halftones. The higher the percentage, the larger the dot will be and the more solid the image will appear. For screen printing, you should set haltones to at least 6 percent, as anything smaller becomes difficult to print accurately, and to no more than 97 percent. Many screen printers will cut the maximum percentile in the upper 80s, as dots that are any larger can merge to create a solid image due to dot gain. Practice makes perfect when formatting your artwork and no two jobs will be exactly alike, so do some experimenting to find what settings work best for you.

To print in halftones, you need to lay down a thin, precise deposit of ink. That means two things: Choosing the right mesh and making sure your screens are properly exposed.

Printing in halftones requires a high mesh count screen. The general mesh count range for printing halftones is 230 to 280, and you need a screen with thin thread. You want your dot to lie down easily on your garment. A thick thread forces you to use more pressure to push the ink through the mesh and onto the garment. You risk getting a heavy deposit and an inaccurate dot. For the same reason, your screens need proper tension. For halftone printing, screen tension should be at least 25 N/cm2. This allows you to print accurately with little pressure, and it means the screen will snap neatly away from the garment after the print stroke.

You’ll also want to watch your screen exposure process. Make sure you’re using a printer that is up to the task of printing accurate halftones. You need an opaque positive that will expose accurately. Try to keep your emulsion thin, as a thicker stencil means a heavier ink deposit. Finally, once the screen has been exposed and rinsed out, hold it up to a light source to make sure that your halftone dots have come through cleanly and your image is accurate.

Again, creating quality halftone images depends on laying down thin dots of ink accurately. It’s inevitable that ink will spread when it hits the substrate, creating a larger dot than the one on the image or on the stencil. If your dot-gain is too large, the halftone dots will merge together to create a solid, blurred print.

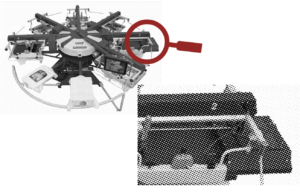

When setting up your press, you need to be sure that your press is in perfect working order. Pallets and print heads can’t be loose. The press should be calibrated so that all blades, screens and pallets are level and parallel. Off-contact distance should be set to 1/8 of an inch so that you don’t need a lot of force to lay down your ink.

You need a sharp, somewhat firm squeegee for halftone printing; you shouldn’t be using the same squeegee that you use for your normal print jobs. If you’re using plastisol ink, you might need to thin your ink so that it flows easily through the mesh. Finally, when you print, you want to make one fast squeegee stroke at a high angle. Keep in mind your goal of laying down your halftone dots lightly and accurately!

Creating high-quality halftone images that will impress your customers will take some practice. We all know that improving your screen prints takes experimentation to find what works best for you and your equipment. We’ve given you some guidelines for creating great halftone images, but these are guidelines, and many screen printers deviate from the guidelines to create a halftone screen printing process they feel comfortable with.

In the end, learning to screen print halftone images will provide a payoff: You’ll create more detailed images that help you to attract new customers and provide your existing customers with more options.

Looking for some more ways to separate your screen printing shop from the pack? Check out this blog post:

Make Your Screen Printing Shop Stand Out from the Competition

Your message was successfully sent!