How an Automatic Silk Screen Machine Can Transform Your Print Shop

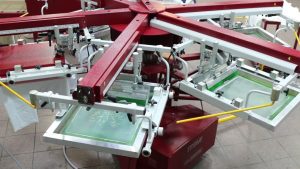

Running a screen printing business means balancing efficiency, quality, and customer satisfaction. Manual presses can limit growth, but upgrading to an automatic silk screen machine changes the game. In this video, Anatol demonstrates how automation makes screen printing faster, more consistent, and more profitable for modern shops.

Unlike manual equipment, automated presses reduce human error, improve registration accuracy, and allow operators to handle more orders with less physical strain. For shop owners, this means more reliable turnaround times, happier customers, and the ability to take on larger contracts with confidence.

Benefits of an Automatic Silk Screen Machine

The advantages go far beyond speed. An automatic system reduces labor expenses, lowers production stress, and ensures every print looks identical across thousands of impressions. With touchscreen controls and energy-efficient features, automation also helps cut operational costs. These savings free up resources to invest in design, marketing, and customer service.

Automation is not just about machines — it’s about unlocking new opportunities. By integrating this technology, screen printing shops can scale their business while maintaining quality that keeps clients coming back. This video highlights how easily an automated press can fit into your workflow and deliver measurable results from day one.

To learn more about when to switch to automatic, visit Anatol blog or check out the valuable resources on the Anatol Automatic Presses website.