Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Traditional pneumatic screen printing presses rely on air compressors, which can cause issues like air leaks, moisture buildup, and high maintenance costs. The Anatol VOLT, the industry’s first all-electric screen printing machine, transforms your print shop by eliminating compressed air. It offers unmatched screen printing energy efficiency, precision, and ease of use. This article highlights the key Anatol VOLT advantages and why it’s the future of pneumatic vs electric screen printing. Discover the VOLT.

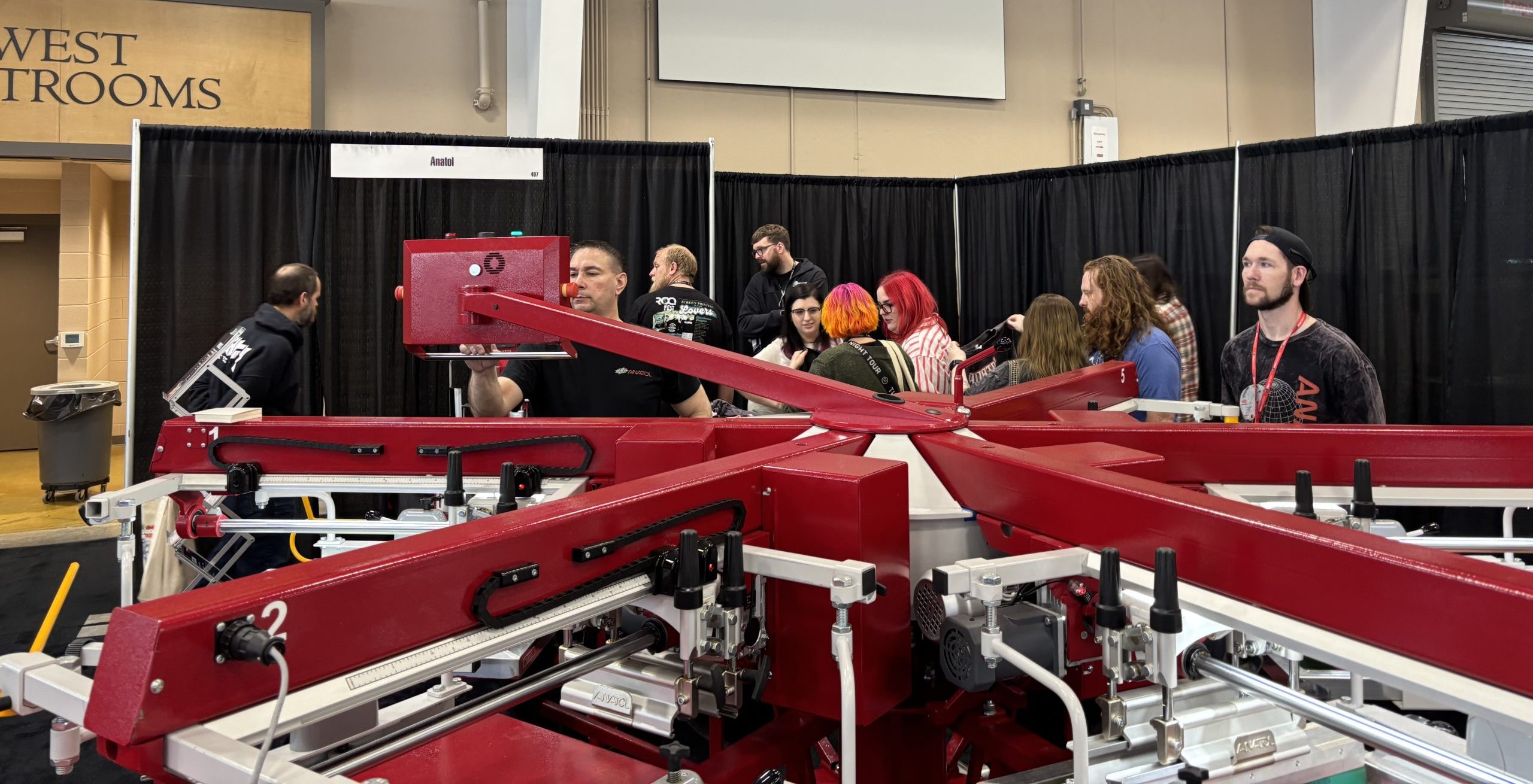

We have seen this machine transform shops, and make production simpler and more efficient. Recently we had the pleasure of catching up with a phenomenal printer-John from Supertight Print Club, and he shared his thoughts on why this machine is such a game-changer:

“The VOLT is an all-electric, high quality automatic shirt printing monster. It’s quiet. It’s intelligent. It’s efficient. While the industry keeps pushing processes that churns out artificial and cheap-looking results, Anatol doubled down to refine the process that remains second to none. As a seasoned printer and heavily invested in the craft- I appreciated that. The VOLT isn’t built to reinvent automatic screen printing; but it definitely made its own lane to modernize and perfect it.”

Our engineering revolves around what screen printers need for the highest quality results, and feedback like this makes it clear to us that the countless hours of research and development are well worth it to serve our customers and make their operation more effective.

Now, lets take a look at some of the specific reasons as to why the VOLT stands out in the world of screen printing:

The electric screen printing press eliminates the need for an air compressor, delivering significant benefits for your shop:

The Anatol VOLT uses advanced servo-driven indexers and print heads for superior precision, setting it apart in pneumatic vs electric screen printing comparisons:

The VOLT is designed for screen printing energy efficiency, helping shops reduce operational costs while maintaining high performance:

The all-electric screen printing machine simplifies setup and maintenance, making it ideal for busy print shops:

Pneumatic presses, long the industry standard, come with challenges like air leaks, moisture buildup, and constant maintenance that reduce productivity and increase costs. The Anatol VOLT advantages address these issues, offering a smarter, more efficient solution. Available in models S, M, L, and XL (6 stations/4 colors to 20 stations/18 colors), the VOLT suits shops of all sizes. Its servo-driven indexers, optional servo print heads, laser alignment, and Speed Clamps streamline operations. Printers worldwide praise the VOLT, with one user stating, “The VOLT optimizes production, allowing us to print large quantities faster. Our production has tripled compared to manual presses.” Another noted, “It’s quiet and extremely efficient, giving me more time to focus on my business.”

The Anatol VOLT is a game-changer for modern screen printing. By eliminating pneumatic systems, it delivers screen printing energy efficiency, higher precision, and lower operating costs. Whether you’re transitioning to automation or running a large operation, the VOLT boosts productivity, reduces waste, and maximizes profitability. Contact Anatol today to explore how the all-electric screen printing machine can transform your business!

Your message was successfully sent!