GOCCOPRO QS2536 – Large Format Direct-to-Screen Imaging

The GOCCOPRO QS2536 brings large-format, commercial-grade direct-to-screen (DTS) imaging to professional screen printers. Capable of producing A2-size screens up to 457 mm wide and 759 mm long, it delivers ultra-fine photo-quality output at an impressive 600 × 1200 dpi resolution.

Designed for trade printers and high-volume production, the QS2536 integrates seamlessly into automated carousel and dryer systems, offering faster screen preparation, lower operating costs, and a significantly higher return on investment compared to traditional chemical emulsion processes.

With true DTS technology, the QS2536 eliminates the need for films, darkrooms, washouts, and emulsions, allowing you to create professional-quality screens directly from your computer in minutes. The result is a clean, efficient, and eco-friendly workflow that maintains the same level of detail and tonal range as traditional methods — and often exceeds it.

The QS2536 operates through a dedicated printer driver, enabling direct printing from any standard design software without the need for RIP programs, file conversions, or complex setups. Whether you’re producing solid graphics, gradients, or detailed photographic images, the QS2536 delivers perfect registration, high precision, and consistent results every time.

Experience faster turnaround times, reduced labor, and exceptional image quality — all in one intelligent, chemical-free system designed to redefine modern screen printing.

The new screen printing standard / RISO Dry Thermal Screen Making System

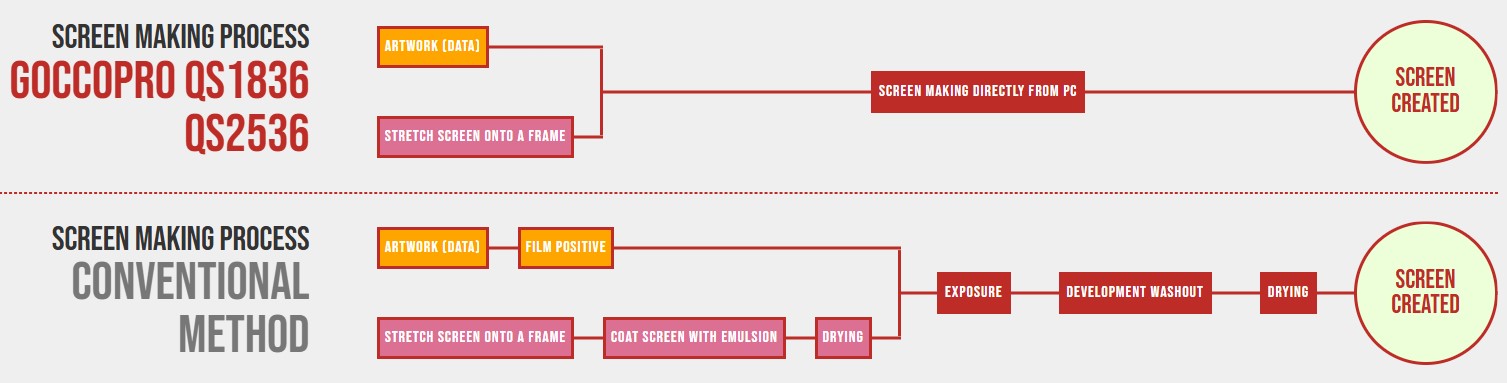

Check out this comparison of the GOCCOPRO screen making process versus traditional screen making to see how GOCCOPRO can save you time, money and labor and help you run a more efficient shop.

GOCCOPRO QS2536 – True Direct-to-Screen Imaging

Experience true direct-to-screen imaging with the GOCCOPRO QS2536, designed for trade-quality flatbed digital screen production. Create both small and large screens with unmatched precision — no washout, no coatings, no chemicals.

Perfect for trade printers with high-volume demands, the QS2536 brings professional-grade efficiency and quality to every production environment.

Direct from Computer to Screen

The QS2536 eliminates the need for films, carbon copies, and manual artwork transfers.

This direct workflow:

- Improves image quality and consistency

- Reduces production costs

- Accelerates turnaround time — making screen creation faster and easier than ever before

Print from Any Program

Using a dedicated printer driver, the QS2536 allows you to print directly from any software that includes a standard print function.

Unlike the MiScreen model, no additional software or file import steps are required — ensuring maximum speed, flexibility, and ease of use from any design application.

Single-Head Imaging Technology

Equipped with a powerful 457 mm-wide Thermal Print Head (TPH), the QS2536 images in a single pass, delivering:

- Superior accuracy and sharpness

- Faster production

- No banding, gaps, or overburn

The QS2536 produces full A2-size screens (457 × 759 mm) at an ultra-fine 600 × 1200 dpi resolution, achieving true photo-quality imaging.

Image Specifications

- Minimum size: 10 × 10 mm

- Maximum size: 457 × 759 mm (with 20 mm frame thickness) / 455 × 734 mm (with 45 mm frame thickness)

Quick, simple, easy operation

- No screen making experience required

- Work directly from computer to screen

- Eliminates steps like exposure and drying

Compact workspace

- Compact size fits on a table

- No need for darkrooms and washout booths

- No need to store large number of screens

Save on time and labor

- Perfect for short-run printing and test production

- Otherwise outsourced jobs can be profitably completed in-house

Easy on the environment

- No need for emulsions and washout

- Dry screen making process with thermal screen technology

Customize Easily

- Direct from PC to screen — no intermediate steps.

- No screen-printing experience required.

- Anyone can produce professional-quality screens in minutes.

Customize Affordably

- Consistent low cost — the price per screen remains the same every time.

- Eliminate traditional expenses: emulsions, films, photoliths, water, and other chemicals.

- Fast, efficient, and profitable, even for short-run or one-off jobs.

Customize Without Graphic Limits

- High-definition image quality with 600 × 600 dpi resolution.

- Reproduce solids, gradients, and fine details with precision.

- Achieve perfect results, even from lower-quality artwork files.

Customize Quickly

- Screens ready in just a few minutes.

- Always meet production deadlines.

- Make small, urgent orders profitable thanks to reduced setup time.

Customize Cleanly

- No emulsion or chemical processes.

- No washing, water, or recovery agents required.

- No odors or liquid waste — completely eco-friendly operation.

Customize in a Compact Space

- No need for darkrooms, exposure units, or water washout systems.

- No bulky screen storage or photolith printers.

- Compact, all-digital workflow — perfect for small studios and workshops.

Anatol Support Contacts

We are always ready to help!

847-582-1825Where to buy

Anatol’s direct sales team is always ready to share their experience and expertise to help you find the right screen printing machine for your business’s needs.

Where to buyQuestions & Answers

Need help? Have Questions? Want answers?

We’ve compiled a list of commonly asked questions our customers ask most frequently. You’ll find your answers here.