The textile printing industry is constantly evolving. To stay competitive, businesses are always looking for ways to boost productivity, expand their services, and work more efficiently.

Some print shops focus only on digital printing, while others rely solely on screen printing. Each method has its own strengths and ideal use cases.

Today, many forward-thinking shops are embracing a hybrid approach. Using both digital and screen printing methods lets print shops create high-quality prints faster and more flexibly. This approach also helps them get the most out of their current equipment.

The Power of Hybrid Printing

Digital printing has become popular recently because it can quickly create high-resolution, full-color designs with little setup. It’s an ideal solution for short runs and customized prints.

Screen printing, on the other hand, is still the best choice for large orders. It provides durable prints, bright colors, and is cost-effective for bulk production.

By combining these methods, print shops can serve a wider range of clients and job types. This approach helps increase profits and make operations run more smoothly.

Where Screen Printing Excels

- Bulk production: Once the screens are set up, printing thousands of shirts is fast and cost-effective.

- Color vibrancy: Screen printing allows for rich, opaque ink layers, making designs pop.

- Special inks and effects: Screen printing can use special inks like metallic, puff, and glow-in-the-dark that are difficult to achieve with digital printing.

- Lower cost per item for large orders: Screen printing is much cheaper per unit than digital printing when printing in bulk.

Where Digital Printing Shines

- Quick turnaround: No need for screen setup means digital printing is ideal for rush orders.

- Full-color and lifelike designs: Complex artwork, gradients, and fine details are easier to achieve with digital methods.

- On-demand production: Digital printing allows for cost-effective single-piece orders, reducing inventory waste.

- Easy to change: Great for personalized printing, like adding names and numbers on jerseys.

The Best of Both Worlds: Integrating Screen and Digital Printing

Rather than choosing between the two technologies, many textile print shops are seeing significant benefits in a hybrid approach. Using digital printing for small or custom jobs and screen printing for large orders helps businesses save time and make more money.

Key Strategies for a Successful Hybrid Printing Setup

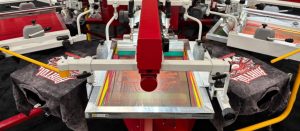

Invest in Automated Screen Printing Equipment

Automation is a game-changer for textile shops that want to optimize their screen printing workflow. Anatol’s automated screen printing presses, such as the Volt and Titan series, increase production speed, boost accuracy, and maintain steady quality. By automating the screen printing process, shops can handle larger orders efficiently while reducing labor costs and increasing output.

Enhance Digital Printing with Complementary Equipment

For shops already using DTG or DTF printers, Anatol offers essential accessories that complement their digital workflow. A high-quality heat press is a must-have for curing digital prints, ensuring proper adhesion and longevity. Flash cure units help improve hybrid designs by curing screen-printed base layers that support bright digital prints.

Use Screen Printing for Underbases and Special Effects

A great way to combine screen and digital printing is to use screen printing for underbases. A white underbase can help digital prints appear more vivid, especially on dark garments. Screen printing also allows for special effects like foil, puff, or high-density prints, adding extra impact to your designs.

Optimize Workflow with a Well-Designed Production Layout

Hybrid printing setups require efficient production flow to minimize bottlenecks. A well-planned layout of digital printers, screen presses, flash dryers, and heat presses can speed up your workflow and reduce production time.

Train Your Team on Both Technologies

Maximizing productivity with a hybrid approach requires skilled operators who understand the nuances of both digital and screen printing. Providing ongoing training ensures your team can switch between methods seamlessly, troubleshoot issues, and maintain high-quality standards.

Boosting Profits with a Hybrid Approach

- Broaden your services: Use digital printing for custom jobs and screen printing for bulk orders to attract more customers.

- Increase production capacity: Use automation to boost efficiency and meet tight deadlines without sacrificing quality.

- Save on costs and materials by selecting: the most efficient printing method for each project.

- Expand design: options by blending digital elements with textured screen prints and specialty inks for distinctive, premium results.

Partnering with Anatol for a Seamless Transition

Anatol Equipment provides advanced screen printing technology that helps print shops grow and succeed. Anatol provides everything from automated screen presses to digital printing accessories—designed to work smoothly in a hybrid setup.

A hybrid approach helps print shops discover new opportunities, work more efficiently, and stay competitive in textile printing. Combining automated screen printing with flexible digital printing helps your business succeed in today’s fast-changing market.