Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolutionizing the screen printing industry through cutting-edge technology and quality service

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Screen printing, one of the most versatile and widely used printing methods today, has a rich history that spans centuries. From its ancient origins to modern technologies, the evolution of screen printing shows human skill and creativity. This article explores the fascinating history of screen printing, highlighting important milestones, techniques, and innovations that shaped the industry.

Screen printers push ink through a mesh screen onto a surface to create a design. This method is popular because it creates bright, lasting prints on many materials like fabric, paper, glass, and metal. Let us explore the history of screen printing.

The roots of screen printing can be traced back thousands of years to ancient civilizations. While the technique has evolved significantly, its core principles remain surprisingly similar.

The earliest forms of screen printing emerged in ancient China during the Song Dynasty (960–1279 CE). Artisans used stencils made from paper or leaves to apply patterns onto fabrics and other surfaces. Artisans often reinforced these early stencils with human hair or silk threads, creating a primitive mesh-like structure.

At about the same time, artisans in Japan and Egypt also used stencils to decorate textiles and walls. These ancient screen printing techniques laid the foundation for more advanced methods.

By the 18th century, silk became a critical material in screen printing, giving rise to the term “silk screening.” In Japan, artisans created a technique called katagami. They made stencils from mulberry paper coated with persimmon juice. Artisans stretched these stencils over silk screens to create intricate designs for kimonos and other textiles.

Screen printing began to gain traction in Europe and the United States in the late 19th and early 20th centuries. As factories grew, new tools and materials greatly changed the technique.

In the early 1900s, screen printing transitioned from a craft to an industrial process. In England, printers began using wooden frames with silk screens to produce wallpaper and fabric designs. At the same time in the United States, Samuel Simon patented screen printing in 1907. He created a method to print multi-color designs using stencils.

The 1960s marked a turning point for screen printing, thanks to the Pop Art movement. Artists like Andy Warhol popularized silk screening as a fine art medium. With his Marilyn Monroe and Campbell’s Soup Cans series, Warhol revealed how screen printing could produce striking, colorful art.

As technology advanced, so did screen printing. The late 20th and early 21st centuries brought automation, digital integration, and eco-friendly innovations to the industry.

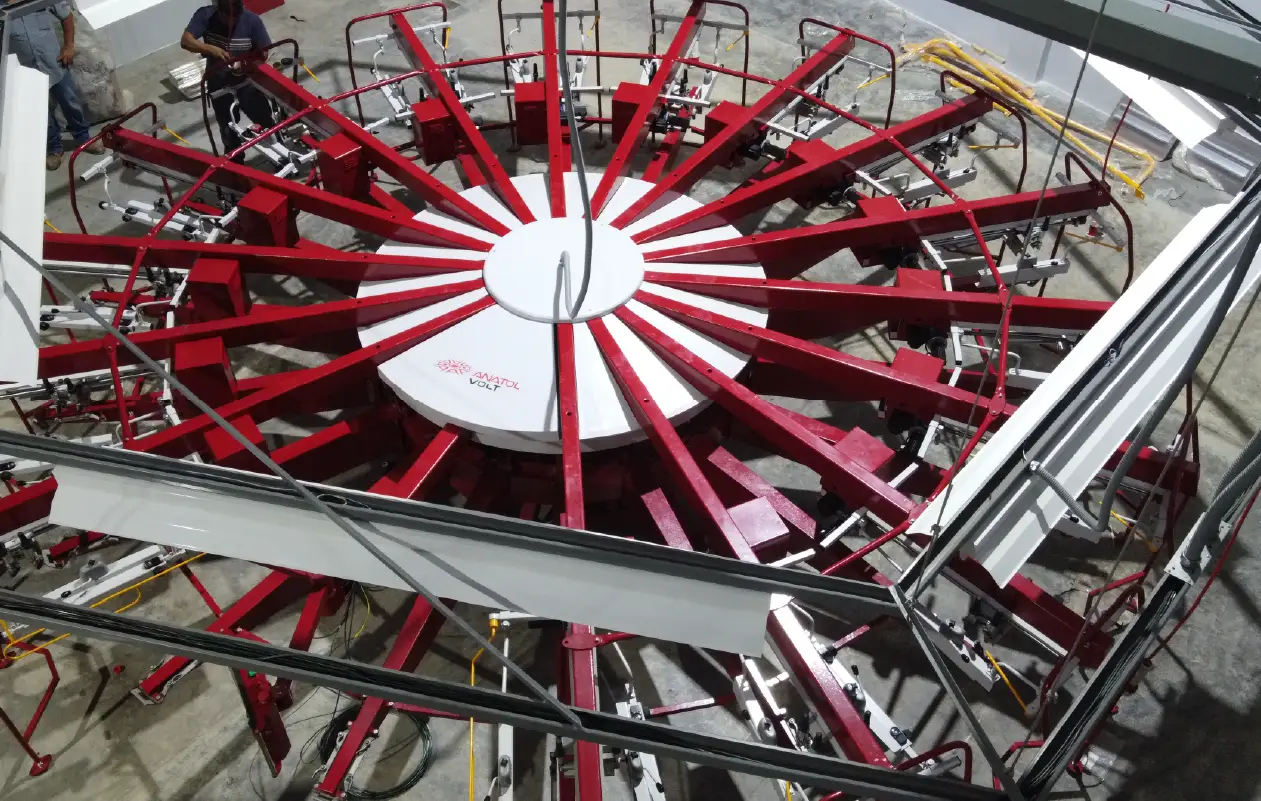

In the 1980s, the introduction of automated screen printing machines transformed the industry. These machines allowed for faster production, greater precision, and the ability to print on a wide range of substrates.

At Anatol Equipment, we specialize in cutting-edge screen printing machines that combine speed, precision, and reliability. We design our equipment to meet the needs of modern print shops, from small businesses to high-volume producers.

The rise of digital technology in the 2000s introduced digital screen printing and hybrid printing systems. These methods combine traditional screen printing with digital imaging, allowing for greater flexibility and personal touches.

These advancements have made screen printing more efficient and environmentally friendly, aligning with the growing demand for sustainable practices.

Caring for the environment is a major focus in modern screen printing. Screen printers are choosing greener materials, like water-based inks and energy-efficient machines, to help protect the environment.

At Anatol, we value protecting the environment and provide equipment that supports eco-friendly printing without losing quality.

Today, screen printing is a thriving industry that blends traditional craftsmanship with state-of-the-art technology. From small artisan studios to large factories, screen printing is a trusted way to create durable, high-quality designs.

Screen printing is used across a wide range of industries, including:

Despite the rise of digital printing, screen printing remains popular because of its:

As we look to the future, screen printing is poised for further innovation. Emerging trends include:

At Anatol Equipment, we are proud to lead these advancements and offer innovative solutions for the screen printing industry.

The history of screen printing is a testament to human creativity and technological progress. From ancient stencils in China to modern automated machines, screen printing has evolved into a dynamic and versatile industry. No matter if you work for fun, art, or business, knowing the history of screen printing can encourage you to discover its full potential.

Are you prepared to begin your screen printing venture? Explore Anatol’s range of screen printing equipment to bring your designs to life with precision and efficiency. For more information about our screen printing equipment, please feel free to get in touch with our team.

Your message was successfully sent!