Starting a screen printing business can seem overwhelming, but planning for the essentials can make it easier.

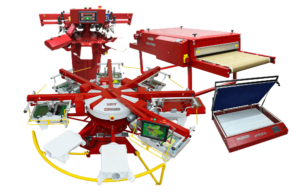

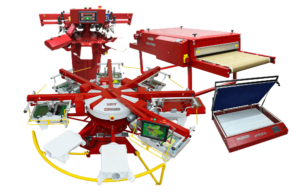

While it’s true that a screen printing production floor can seem busy and crowded with machinery, there are actually only a few pieces you’ll need — from pre-press to printing to post-press — to start producing screen printed goods.

Pre-Press Equipment

In screen printing, there’s quite a bit to do before your products get to the press. The pre-press process involves preparing the artwork and screens you will use to lay down your screen prints. Pre-press necessities include:

- A computer with design software to create graphics.

- Printer and film. To make stencils on your screens, you will print the graphics you’ve created onto clear film. You need a printer that will lay down an opaque black ink that will totally block out UV light when you expose your screens.

- Screens. Of course, you’ll need screens for your screen printing shop! There are a lot of screens options available, but you’ll want to stock a small supply of the most commonly used screens as you get started.

- Emulsion. Screens are coated with a special emulsion that hardens when exposed to UV light to create a stencil.

- Drying racks, whether you purchase screen drying racks or build your own, you will need a place to lay screens horizontally while the emulsion dries.

- Exposure unit. Emulsion-coated screens are placed in a special exposure unit that provides the UV needed to cure the stencils.

- Washout station and water source. A washout station gives you a place to rinse the stenciled area out of the screen after exposure and to reclaim screens after press runs. You can use either a regular garden hose or a pressure washer as a water source in your washout station.

Screen Printing Equipment

For laying down prints, there are a few pieces of screen printing equipment you’ll need, including:

- A press. Of course, the press is the heart of every print shop. Most shops start with a manual machine and upgrade to an automatic as they grow. While presses come in many configurations, it’s wise to start with a six-color press, which will allow you to print nearly any job.

- Ink. You will have to choose from traditional plastisol or water-based and discharge inks. As you start, you can purchase a basic ink mixing pack, along with some regular colors — such as black, white and local school colors — that you know you’ll use often. You also will want plastic containers and ink scoops to help you handle your ink. Some shops also use scales and mixers to help prepare their inks.

- Squeegees. Squeegees are used to pull ink across the screen and lay down the print. Like screens, there are many different types of squeegees, and you will want to stock a few basics to see you through your usual print jobs.

- Substrates. You will need whatever object you’re going to be laying your prints down on, whether it’s T-shirts, sweatshirts, tote bags or banners.

- Flash cure unit. Not all shops start with a flash cure unit, but it is a valued piece of equipment on most screen-printing floors. A flash cure unit allows you to partially cure or “gel” your inks so you can print white underbases or overlapping colors.

Post-Press Equipment

Post-press, there’s one necessary piece of equipment: The conveyor dryer. Conveyor dryers heat your ink to the curing temperature so that your prints will last. You also will want to purchase some sort of heat sensor, whether it’s a heat gun or heat tape, to check that your ink has reached the proper curing temperature as it comes out of the dryer. From there, you will need bags and boxes to get your finished garments packaged up for your customers.

While researching screen printing equipment can leave you feeling like you’ve traveled down a rabbit hole, there’s relatively little you need to start your own screen printing business. With a few quality basics, you will be churning out your own screen printed apparel in no time.

To request a calculation of equipment and its payback, fill out the form below ⬇️

For more information on screen printing flash cures, check out these blog posts:

Getting the Most out of Your Screen Printing Flash Cure

Safety Tips for Operating Your Screen Printing Flash Cure

A General Guide to Quartz Flash Settings for Screen Printing