Descripción

Innovación Eficiente

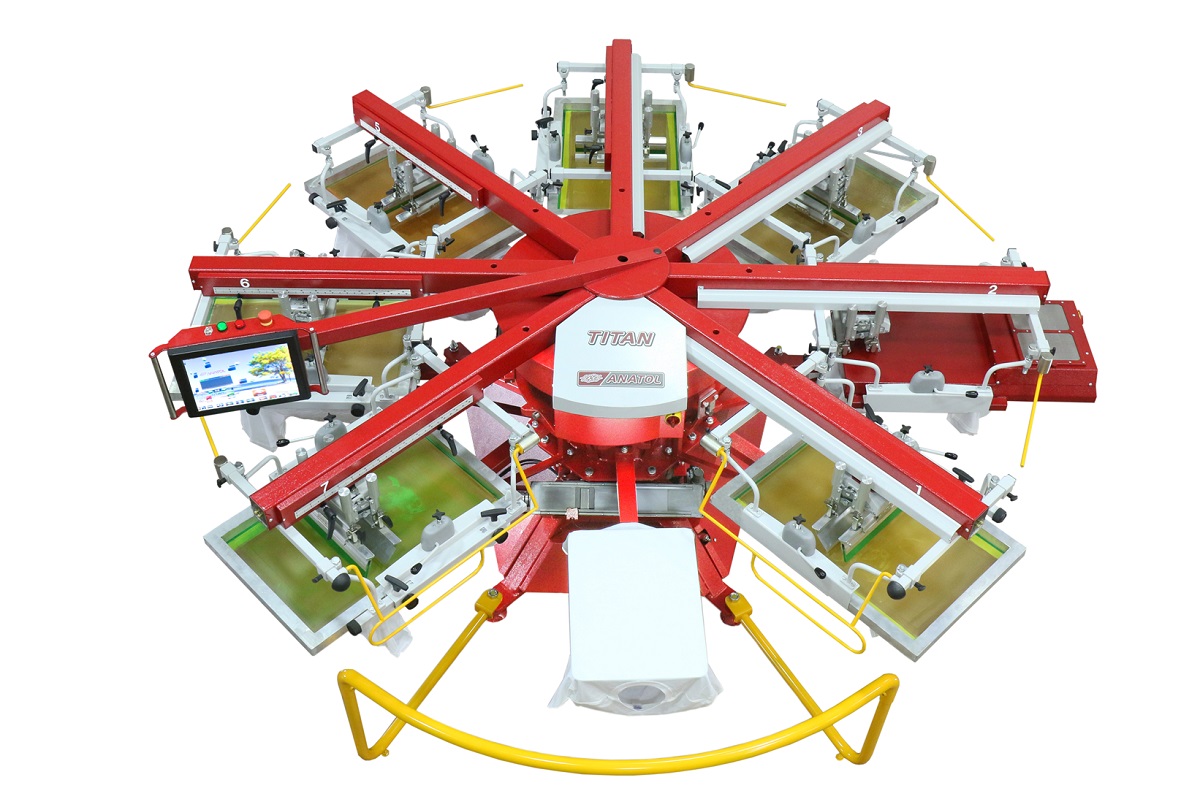

Con las máquinas de impresión de textil Titan AAA y ASA Ahorre miles en costos de mantenimiento y tiempo perdido. Estas prensas utilizan sólo dos (2) cilindros. Se eliminaron 4 cilindros de bloqueo, 4 cilindros de squeegee / flood bar y 4 cilindros del carro para agarre de squeegee / flood bar por cabeza. El estándar de la industria utiliza 10-12 cilindros por cabeza.

Usted utilizará un compresor más pequeño que significa menos costos de operación y la capacidad de funcionar en el “más complicado” taller de serigrafía.

Las exclusivas abrazaderas rápidas sin aire aseguran una sujeción uniforme en cualquier tipo de bastidor o grosor, ahorrándote el desperdicio de las mangueras de aire o de los interruptores de palanca con fugas.

En la Titan encontrará tecnología avanzada que sólo se obtiene en una máquina de impresión textil de alto nivel

Las máquinas de impresión textile Titan ASA y ASE de Anatol tienen un servo indexer de alta calidad de tipo tornillo lineal utilizado a veces en la industria en modelos de alta gama. El estándar de la industria para las prensas automáticas de alto nivel es a menudo el estilo de el impulso del engranaje o del brazo de manivela o el motor eléctrico.

El cilindro de levante tiene el sistema Click de fuera de contacto que se ajusta en incrementos de 0,005 “hasta 2/5 pulgadas, resultando en 80 configuraciones fuera de contacto – muy por encima del estándar de la industria.

Características estándar

Heads Up Feature

- On machines with an odd number of print heads, this allows you to raise the last head on a hinge to create dedicated loading and unloading stations.

- It’s like getting two machines in one. For example, a 10 station 9 color machine can become a 10 station 8 color machine when you need two operators to load and unload and aren’t using the last head, allowing you to work faster.

Registration

- True three-point micro-registration of the screen (front-back, left-right, rotational movement) allowing for precise and quick adjustments

- Compatible with Anatol’s ARME pre-registration system, as well as many other common pre-registration systems available on the market

Control Interface

- Aries 2 OS: same industry-leading, intuitive operating system found on our top-of-the-line VOLT presses

- 15’’ touchscreen with one-touch access to all job settings and machine functions for quick and easy setups

- Rotating boom arm allows easy access to the touchscreen from any print head

- Quick access to the operator’s manual

Functions

- Save all parameters of a stored job: indexing speed, number of strokes, flash cure time and temperature, ink colors

- Set pallet preheat temperature with smart flash

Central Off-Contact

- Gauged click mechanism allows for precise adjustments up to 2/5 inch – 68 settings for off-contact, well above the industry standard for maximum control when printing on various substrates or using specialty inks

- Most advanced mechanical central off-contact on the market

Print Heads

- Pneumatically-driven print heads (AAA and ASA models) or A/C electric print heads (ASE models)

- Independent flood/print speed contro

- Single-handed squeegee/flood bar adjustments with a range of 0° -30°

- Front and rear stroke adjustments

- Gauged squeegee/flood bar knobs provide easy depth adjustments

- Easily adjustable side screen clamps accommodate a wide range of screen sizes

Safety System

- Ensure safety during press setup and operation with ourpatented safety bars located between each print head and on each side of the load and unload stations

Skip Shirt & Smash Button

- Save time and supplies by preventing the press from printing on empty pallets with our Skip Shirt function

- Smash button allows for easy skipping of improperly loaded shirts to prevent misprints

Indexing System

- Servo indexer allows for clockwise, counterclockwise and half indexing (ASA and ASE models)

- Pneumatic indexer with clockwise direction (AAA models)

- Step-Back and Multi Step-Back programs available on models with servo indexers, and on pneumatic models in configurations of 6 stations/5 colors or smaller

Pallet System

- Slide-style pallets allow for adjustments in print location

- Tool-free locking

- Precise four-point pallet leveling system

- 16’’x 22’’ solid aluminum, low profile rubber coated pallets standard, with a wide variety of specialty and custom pallets available separately

- Laser alignment system for quick and easy pallet location and apparel alignment

Options

- Quartz flash cure units

- Quick-release pallet system

- Foot pedal to control indexing

- Individual print head controls

- Special sizing available for doorways as small as 28’’

| AAA | ASA | ASE | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Air Requirement @ 90 PSI |

Power Requirement | Diameter | Air Requirement @ 90 PSI |

Power Requirement | Diameter | Air Requirement @ 90 PSI |

Power Requirement | Diameter |

| 6/4 S | 9.7 SCFM (274 l/min) |

1ph, 115 VAC, 2A |

9’4” | 7.9 SCFM (223 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

9’4” | 2.0 SCFM (58 l/min) |

1ph, 208 VAC, 10A 3ph, 208 VAC, 6A |

9’4” |

| 6/5 S | 11.3 SCFM (319 l/min) |

1ph, 115 VAC, 2A |

9’4” | 9.5 SCFM (268 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

9’4” | 2.2 SCFM (62 l/min) |

1ph, 208 VAC, 11A 3ph, 208 VAC, 6A |

9’4” |

| 8/6 S | 12.9 SCFM (365 l/min) |

1ph, 115 VAC, 2A |

10’2” | 11.1 SCFM (314 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

10’2” | 2.4 SCFM (68 l/min) |

1ph, 208 VAC, 11A 3ph, 208 VAC, 7A |

10’2” |

| 8/7 S | 14.5 SCFM (410 l/min) |

1ph, 115 VAC, 2A |

10’2” | 12.7 SCFM (359 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

10’2” | 2.5 SCFM (72 l/min) |

1ph, 208 VAC, 12A 3ph, 208 VAC, 7A |

10’2” |

| 10/8 S | 14.3 SCFM (404 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

11’1” | 2.7 SCFM (76 l/min) |

1ph, 208 VAC, 14A 3ph, 208 VAC, 9A |

11’3” | |||

| 10/9 S | 15.9 SCFM (449 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

11’1” | 2.8 SCFM (80 l/min) |

1ph, 208 VAC, 14A 3ph, 208 VAC, 9A |

11’3” | |||

| 12/10 S | 17.5 SCFM (495 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

12’3” | 3.0 SCFM (85 l/min) |

1ph, 208 VAC, 16A 3ph, 208 VAC, 11A |

12’3” | |||

| 12/11 S | 19.1 SCFM (540 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

12’3” | 3.1 SCFM (87 l/min) |

1ph, 208 VAC, 16A 3ph, 208 VAC, 11A |

12’3” | |||

| AAA | ASA | ASE | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Air Requirement @ 90 PSI |

Power Requirement | Diameter | Air Requirement @ 90 PSI |

Power Requirement | Diameter | Air Requirement @ 90 PSI |

Power Requirement | Diameter |

| 6/4 M | 9.8 SCFM (278 l/min) |

1ph, 115 VAC, 2A |

9’8” | 8.1 SCFM (223 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

9’8” | 2.0 SCFM (58 l/min) |

1ph, 208 VAC, 10A 3ph, 208 VAC, 6A |

9’8” |

| 6/5 M | 11.4 SCFM (323 l/min) |

1ph, 115 VAC, 2A |

9’8” | 9.6 SCFM (272 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

9’8” | 2.2 SCFM (62 l/min) |

1ph, 208 VAC, 11A 3ph, 208 VAC, 6A |

9’8” |

| 8/6 M | 13.0 SCFM (369 l/min) |

1ph, 115 VAC, 2A |

10’11” | 11.2 SCFM (318 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

10’11” | 2.4 SCFM (68 l/min) |

1ph, 208 VAC, 11A 3ph, 208 VAC, 7A |

10’11” |

| 8/7 M | 14.6 SCFM (414 l/min) |

1ph, 115 VAC, 2A |

10’11” | 12.9 SCFM (364 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

10’11” | 2.5 SCFM (72 l/min) |

1ph, 208 VAC, 12A 3ph, 208 VAC, 7A |

10’11” |

| 10/8 M | 14.4 SCFM (408 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

12’3” | 2.7 SCFM (76 l/min) |

1ph, 208 VAC, 14A 3ph, 208 VAC, 9A |

12’5” | |||

| 10/9 M | 16.0 SCFM (454 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

12’3” | 2.8 SCFM (80 l/min) |

1ph, 208 VAC, 14A 3ph, 208 VAC, 9A |

12’5” | |||

| 12/10 M | 17.6 SCFM (498 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

13’6” | 3.0 SCFM (85 l/min) |

1ph, 208 VAC, 16A 3ph, 208 VAC, 11A |

13’6” | |||

| 12/11 M | 19.2 SCFM (545 l/min) |

1ph, 208 VAC, 6A 3ph, 208 VAC, 4A |

13’6” | 3.1 SCFM (87 l/min) |

1ph, 208 VAC, 16A 3ph, 208 VAC, 11A |

13’6” | |||

Anatol Support Contacts

Siempre estamos dispuestos a ayudarle!

847-582-1825Dónde comprar

Anatol’s direct sales team is always ready to share their experience and expertise to help you find the right screen printing machine for your business’s needs.

Dónde comprarPreguntas y respuestas

¿Necesitas ayuda? ¿Tiene preguntas? ¿Quieres respuestas?

Hemos compilado una lista de preguntas frecuentes que nuestros clientes hacen con más frecuencia. Encontrarás tus respuestas aquí.