Корзина пуста.

ru

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Телефон: +1 847-367-9760

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

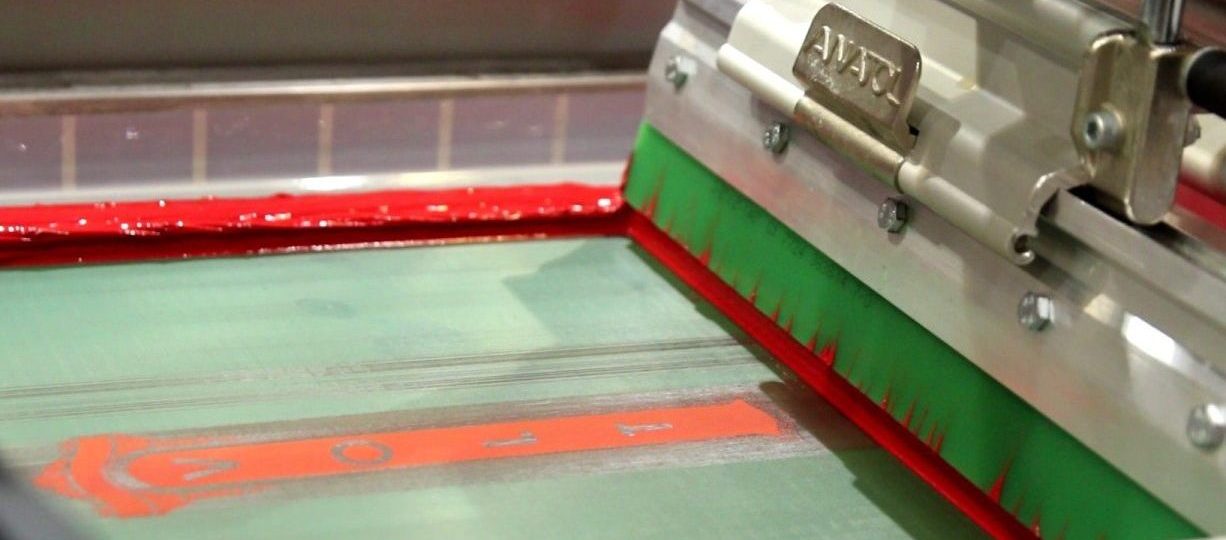

Getting the squeegee pressure right is crucial for perfect screen printing. No matter if you use automatic Anatol machines or a manual press, using the right pressure helps you get bright colors, sharp details, and even prints every time. This guide will teach you how to set your pressure properly, share expert advice, and show how Anatol’s automatic presses make printing easier and better.

In screen printing, the squeegee pushes ink through the mesh of the screen onto the substrate. The pressure applied directly affects the quality of the print. Incorrect squeegee pressure can lead to issues like ink bleeding, uneven prints, or incomplete ink transfer. Here’s why getting it right matters:

Anatol’s advanced screen printing equipment makes adjusting squeegee pressure intuitive and precise, helping you achieve perfect prints every time.

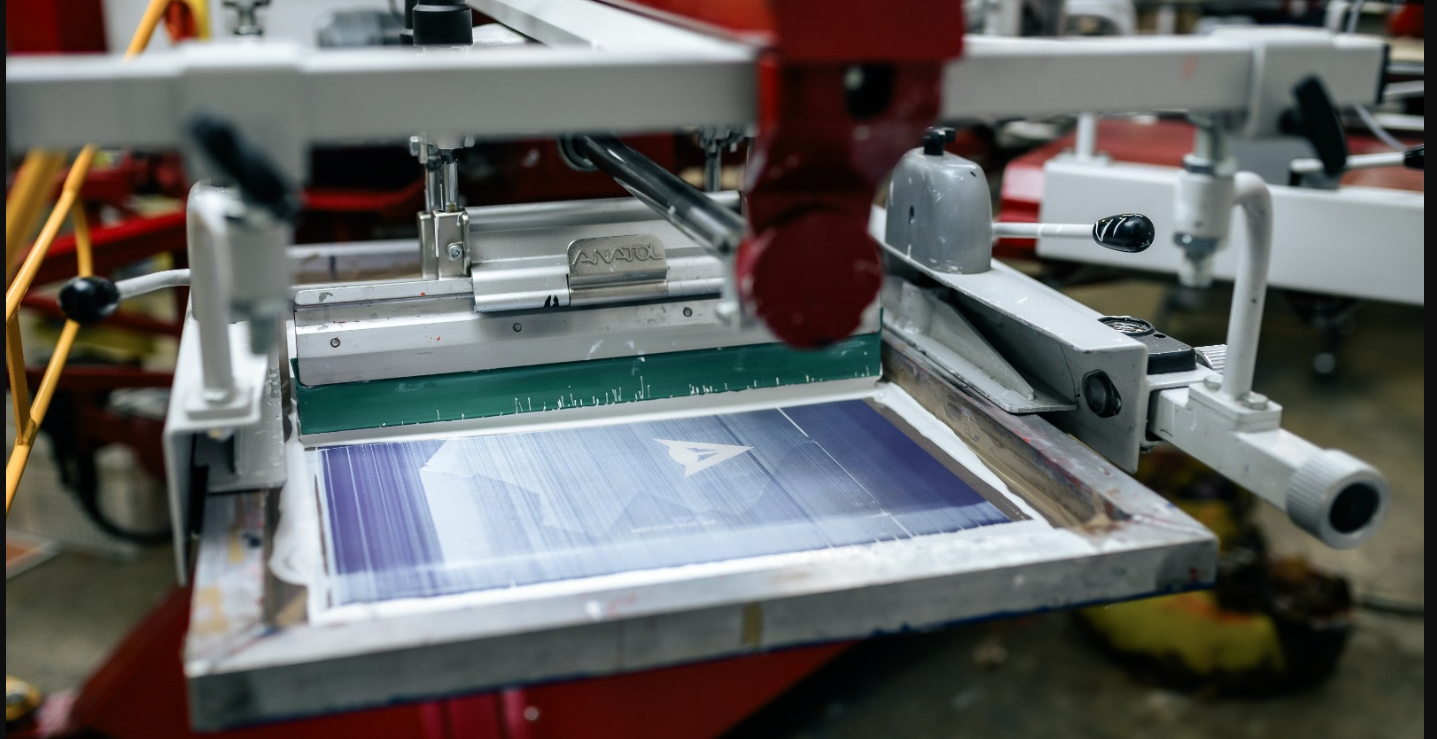

Follow these detailed steps to set squeegee pressure correctly for optimal screen printing results:

Start with a moderate squeegee pressure setting. For manual presses, apply light pressure manually and increase as needed. For Anatol’s VOLT automatic press, use the digital control panel to set a mid-range pressure value. This baseline allows you to test and adjust without making the process too complicated.

Perform a test print on a scrap substrate, such as an old t-shirt or paper. Evaluate the print for clarity, color vibrancy, and edge definition.

If the ink appears too heavy or bleeds, the pressure is too high. If the print is faint, patchy, or lacks detail, the pressure is too low.

Use these observations to guide your adjustments.

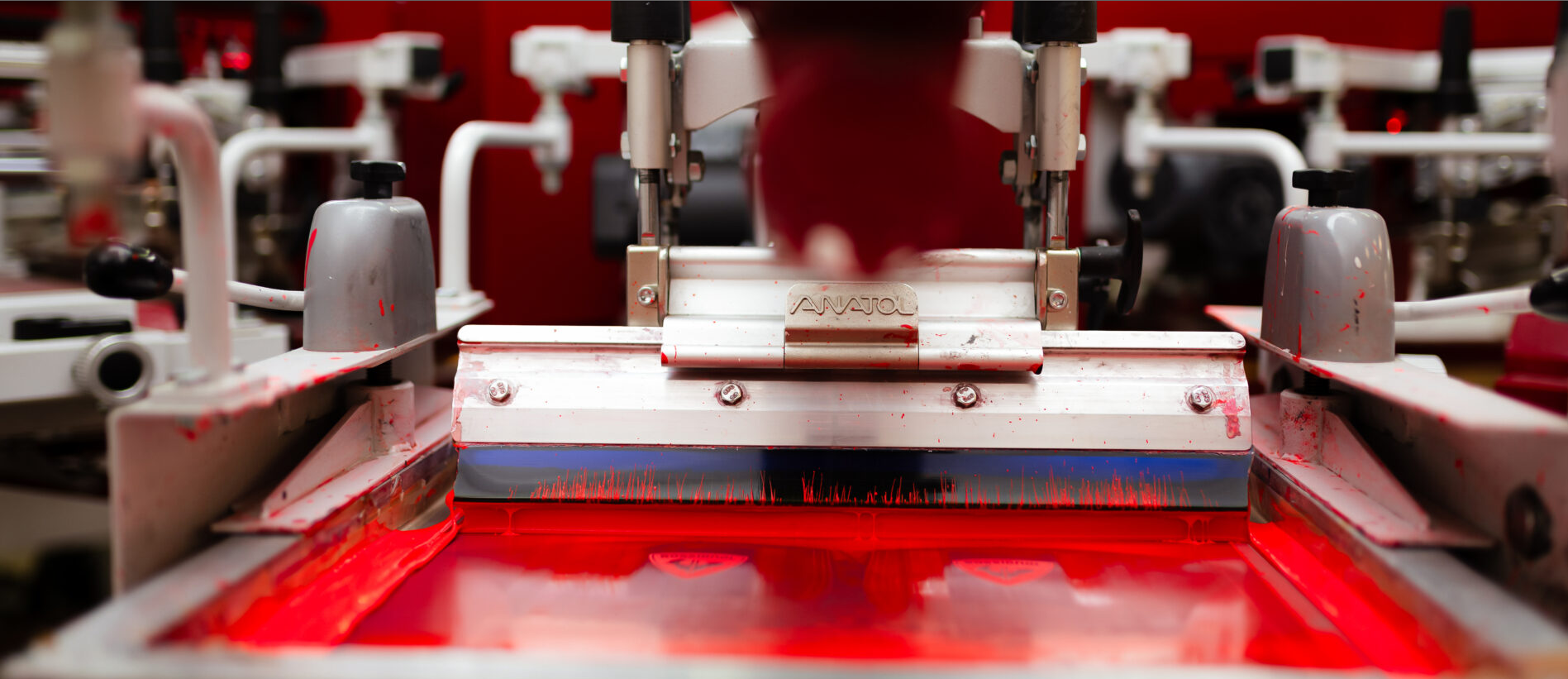

Adjust the squeegee pressure in small increments, testing after each change. Anatol’s automatic presses, like the Anatol Vector, feature micro-adjustment controls for precise tuning. This precision helps you find the optimal pressure quickly, saving time and materials.

Squeegee pressure works in tandem with the squeegee angle and blade condition. A 45-degree angle is typically ideal for most screen printing jobs, as it balances ink transfer and screen contact. Inspect the squeegee blade for nicks, dullness, or wear, as a damaged blade requires more pressure, which can distort prints. Replace worn blades to maintain quality.

Different inks and substrates require unique pressure settings. For example:

Test prints are crucial for fine-tuning settings for each job. Anatol’s equipment simplifies this process with programmable settings for different ink and substrate combinations.

To elevate your screen printing game, incorporate these expert tips when setting squeegee pressure with Anatol equipment:

Avoid these common pitfalls to ensure high-quality prints and efficient production:

For experienced printers, consider these advanced techniques to further refine your squeegee pressure settings:

Anatol’s screen printing machines are engineered for precision, durability, and ease of use. No matter the size of your business or the type of press you use, Anatol’s equipment makes your workflow easier. It makes tasks like adjusting squeegee pressure easier and more precise.

With features like digital controls, sturdy construction, and adjustable settings, you can count on consistent, professional results every time. We design our machines to fit any screen printing business. Whether you need a compact solution like the Anatol VOLT or a high-speed option like the Anatol Vector, we’ve got you covered.

Ready to take your screen printing to the next level? Reach out to Anatol today to check out our complete equipment lineup and learn how we can make perfect prints easy for you.

Your message was successfully sent!