Корзина пуста.

ru

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Телефон: +1 847-367-9760

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

The consistency of screen printing ink is a crucial factor. Often, the thickness and proper mixing of the ink are key to achieving high-quality prints. To ensure top-notch mixing, professionals use Formulator Screen Printing Ink Mixer. These automatic ink mixers provide perfect mixing without air bubbles or clumps. Anatol Equipment Manufacturing Co. is a leader in the screen printing equipment market. The company has introduced a complete line of high-quality ink mixers, which we will cover in this article.

Every experienced screen printer knows that the key to high-quality prints is the consistency of the ink. The quality of the image on fabric depends on proper mixing. If the ink is not thoroughly or evenly mixed, streaks, clumps, or uneven colors may appear on the print. As you can imagine, this would lead to production defects and revenue loss for the business.

To avoid such defects, we recommend automating the mixing process with Anatol Ink Mixers. Properly mixed ink ensures even application, resulting in high-quality, long-lasting prints. Whether you use automatic mixers or mix by hand, achieving an even mixture is a key factor. This seemingly simple process ensures consistent print quality when working with plastisol and water-based inks.

Let’s review each Formulator offered by Anatol and compare their features. After this review, you will be able to choose the right option for your needs. So let’s move on to a detailed look at Anatol Mixers.

The Formulator Mini Ink Mixer is the smallest mixer offered by Anatol. Its compact design is perfect for small screen printing studios with medium workloads.

Key Features:

The Mini Ink Mixer is the ideal solution for print shops specializing in exclusive and custom prints. It ensures even ink mixing, even for the smallest volumes.

The Formulator Standard Ink Mixer is the perfect choice for medium and large print shops. It easily handles large and constant volumes of plastisol ink mixing in production environments.

Key Features:

The Formulator Standard Ink Mixer is designed by Anatol to provide automation for large and medium print shops, requiring fast and uninterrupted ink preparation.

The Formulator Double Ink Mixer takes efficiency to a new level, allowing you to mix two batches of ink simultaneously. It’s ideal for high-volume work or when working with different types of ink at the same time.

Key Benefits:

The Formulator Double Ink Mixer will be useful for large screen printing shops that handle a constant flow of ink mixing.

Anatol’s line of ink mixers for water-based or plastisol inks offers numerous advantages that make them indispensable tools in any screen printing studio. The main benefits include ease of use, programmable mixing modes, touch controls, durable and high-quality construction. These features make the Formulator Ink Mixer key to achieving the best print results, whether in mass production or custom T-shirt printing.

Plastisol inks are thick and require intense mixing to ensure color uniformity on the print. Water-based inks are more fluid and mix easily but tend to form air bubbles. Vigorous mixing can create foam. Anatol’s ink mixers for screen printing are designed to handle both types of ink. The automatic mixers provide even mixing and prevent air bubbles or foam from forming.

Anatol was the first company to introduce modern dual-blade technology. The dual blade reduces ink splashing and prevents air bubbles from forming. Even with large volumes and thick plastisol ink, Anatol mixers ensure smooth, even mixing.

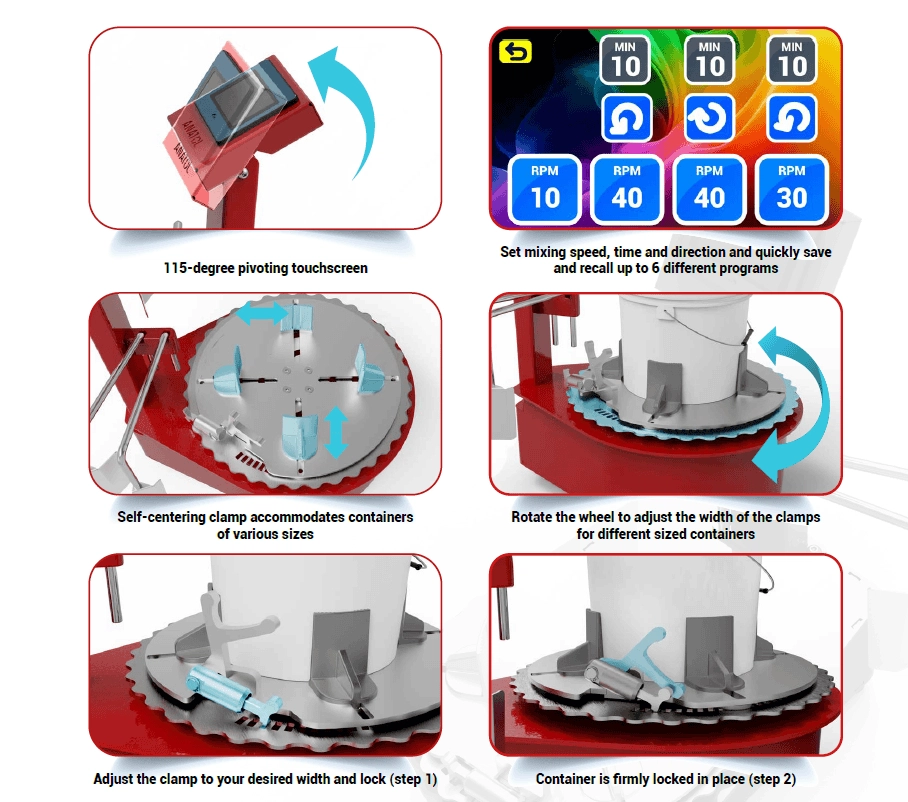

Anatol’s engineering team designed the ink mixers to be simple and efficient to use, even during peak production times. Touch controls allow easy setting and saving of ink mixing parameters. Mode memory is convenient for print shops that use different types of inks in production. They save time in preparing ink for printing and maintain consistent quality for screen printing production.

Features:

Formulator Series Versatility

The entire series of mixers works with various container sizes and ink thicknesses. Their use is convenient for all types of print shops. Small print shops can easily use the Mini Mixer, while large-scale production facilities benefit from the Standard and Double Ink Mixers.

Energy Efficiency and Power Requirements

Formulator mixers are designed to be energy efficient while maintaining high productivity. The powerful motors consume less energy, making these machines a great choice for eco-friendly companies.

Maintenance

Taking care of the Formulator Ink Mixer is simple and requires no special skills. For long-lasting mixer operation, it’s enough to keep it clean. After work, leave the mixer clean by washing the blades and containers. Occasionally check and lubricate moving parts to avoid contamination. Such simple steps ensure the mixer will work efficiently for many years.

“Anatol equipment is made for trouble-free use for years to come.”

When choosing a mixer, consider:

Formulator screen printing ink mixers from Anatol Manufacturing are an excellent choice for any print shop. Speed up your print shop’s workflow and achieve better mixing results.

Optimize another part of your production process—automate ink mixing and improve print quality. Most importantly, with Anatol Ink Mixers, your production will reach maximum stability and productivity.

For more details on prices and models, feel free to leave a request. Our specialists will provide comprehensive information on each model and its features.

Detailed information is also available on our new website screenprinting.equipment

Your message was successfully sent!