Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Success in screen printing depends on finding the right balance between speed and quality. No matter the size of your business, improving your workflow helps you save time, cut expenses, and keep quality high. At Anatol, we understand the importance of efficiency without compromise. This article provides practical tips for increasing print speed while maintaining the high quality your customers expect.

Increasing print speed not only improves productivity, but also helps you meet tight deadlines and grow your business. However, rushing prints can lead to issues like smudging, misalignment, or inconsistent colors. The key is to streamline your workflow strategically. By implementing the right techniques and equipment, you can achieve faster turnaround times without sacrificing quality.

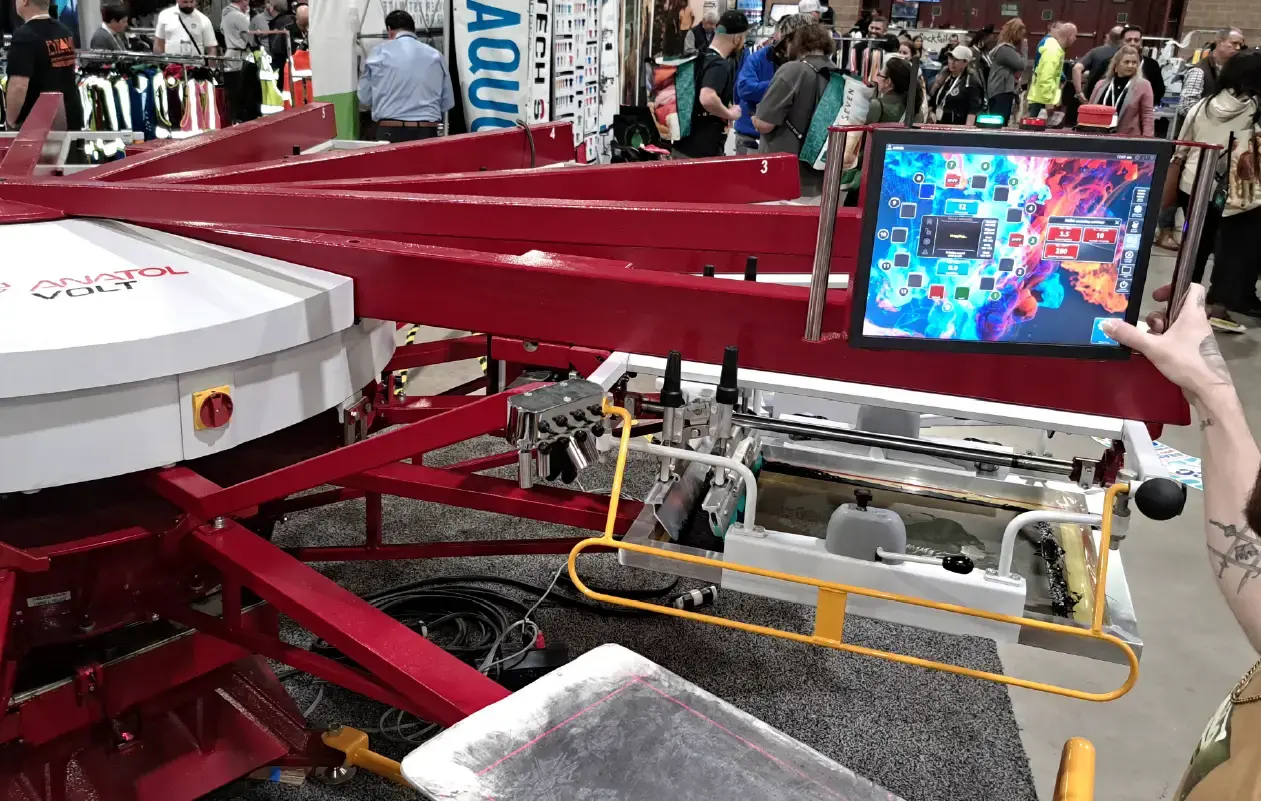

Your equipment plays a pivotal role in balancing speed and quality. Investing in modern, high-performance machines can significantly improve your workflow. Designed for precision and speed, Anatol’s automatic screen printing presses help streamline the production of high-volume orders.

By upgrading to efficient equipment, you’ll reduce manual labor and increase throughput while maintaining crisp, vibrant prints.

Screen preparation is often a bottleneck in screen printing. Streamlining this step can shave valuable time off your production schedule.

For more insights on screen prep, check out our guide on choosing the best screen printing emulsions.

The type of ink you use and how you apply it directly impacts both speed and quality. Plastisol and water-based inks each have their advantages, but choosing the right one for your job is critical.

Complex designs can slow down printing, especially if they require multiple colors or intricate registration. Simplifying artwork and setup can boost efficiency.

For more on artwork prep, read our article on preparing artwork for screen printing.

Curing is a critical step that can make or break your print quality. A slow curing process can create a bottleneck, while rushing it risks under-cured prints that crack or fade.

Learn more about curing techniques in our guide to conveyor dryers.

High-performance equipment alone is not enough, a skilled team is essential to achieve optimal results. Training your staff to work efficiently can significantly boost print speed while maintaining quality.

Continuous improvement is key to long-term efficiency. Regularly evaluate your workflow to identify bottlenecks and areas for improvement.

By analyzing your process, you can make data-driven decisions to optimize both speed and quality.

Optimizing print speed without losing quality is achievable with the right equipment, techniques, and mindset. Improve efficiency without losing quality by modernizing your equipment, refining your process, and developing your team. At Anatol, we’re committed to helping you succeed with innovative solutions tailored to your needs.

Your message was successfully sent!