Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

High density printing elevates screen printing by delivering bold, vibrant designs that stand out on fabric. This technique produces a raised, tactile effect, giving your artwork a premium look and feel.

High density printing helps businesses create better products and allows designers to bring creative ideas to life.

In this article, we’ll explore what high density printing is, how it works, and share expert tips to create stunning, vibrant designs.

High density printing, a unique screen printing method, uses thick ink layers to craft a raised, 3D effect on clothing. Unlike traditional screen printing, which lays down flat ink, high density ink builds up to give designs a textured, bold appearance. This method is perfect for logos, bold graphics, or text that needs to grab attention.

The process involves using a high-density ink and a thick stencil to control the ink’s height. Applying multiple ink layers creates the desired thickness, producing a design that is both visually striking and long-lasting. High density printing enhances apparel like t-shirts, hoodies, and caps, while also elevating promotional items.

Why choose high density printing?

High density printing isn’t just about aesthetics—it’s a strategic choice for brands and designers. Here are the key advantages:

High density inks are formulated to retain their vibrancy even after multiple washes. The thick ink application ensures colors remain bold, making it ideal for designs that need to stand out.

The raised texture invites touch, creating a memorable experience for customers. This sensory element can enhance brand perception and make your products feel premium.

From cotton t-shirts to polyester blends, high density printing works well on various materials. The raised ink enhances contrast and depth, particularly on darker fabrics.

The thick ink layers are resistant to cracking and fading, ensuring your designs stay vibrant over time. This makes it a cost-effective choice for merchandise intended for long-term use.

To unlock the full potential of high density printing, follow these expert tips to craft vibrant, professional designs:

High density printing shines with bold, clean graphics. Avoid overly intricate details, as fine lines may lose clarity in the raised texture. Focus on strong shapes, logos, or typography for maximum impact.

Pro Tip: Use vector-based software like Adobe Illustrator to create sharp, scalable designs. For expert guidance on screen printing, explore our professional design tips. Discover our expert design tips for screen printing.

Color selection is critical for vibrant designs. Opt for high-contrast combinations, like white ink on dark fabrics or neon colors for a bold statement. High density inks amplify color intensity, so test swatches to ensure the final result matches your vision.

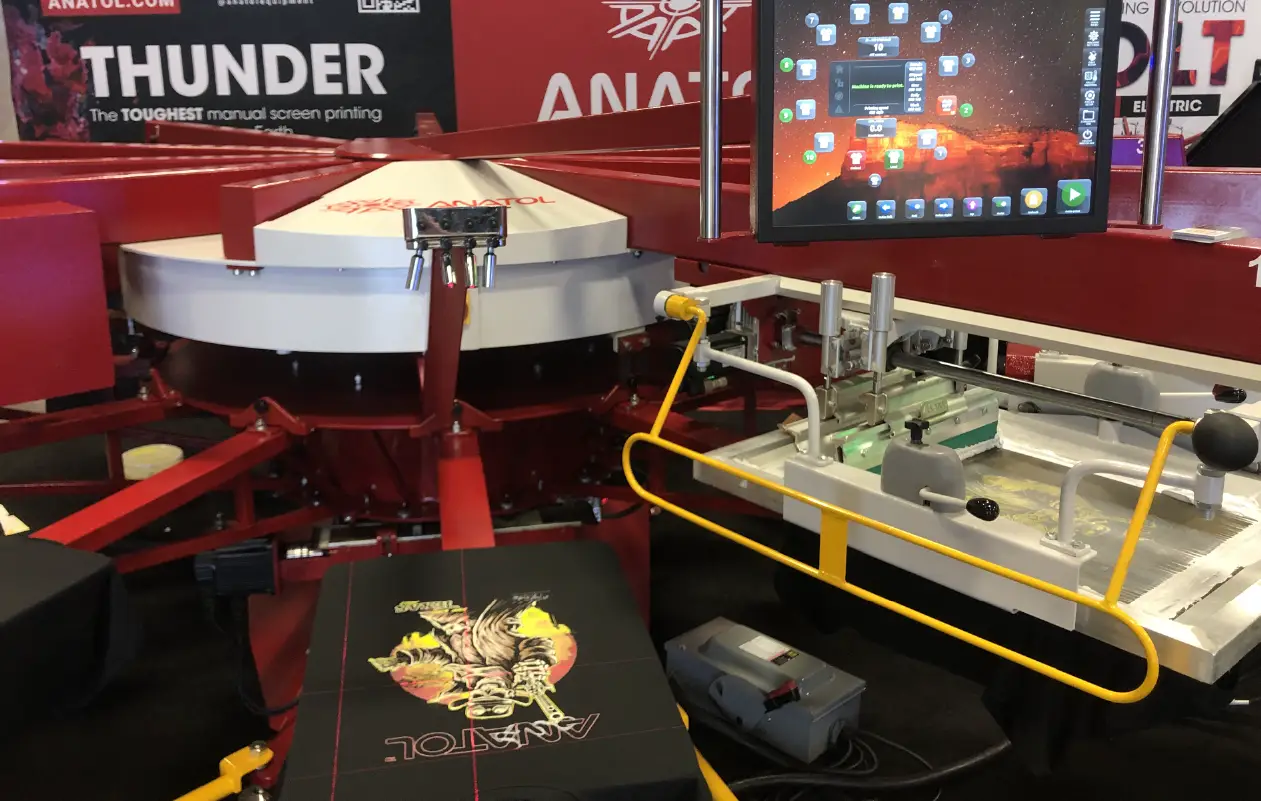

High density printing requires precision equipment, like Anatol’s advanced screen printing presses, to achieve consistent results. Ensure your printer uses high-quality screens and inks to maintain design integrity.

Discover our range of automatic screen printing presses for professional results.

Before committing to a large run, print test samples to check texture, color, and durability. Adjust ink layers or stencil thickness as needed to perfect the design.

Prepared to craft striking, high-density designs that stand out? Contact Anatol Equipment for expert advice and top-tier screen printing solutions.

Your message was successfully sent!