Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

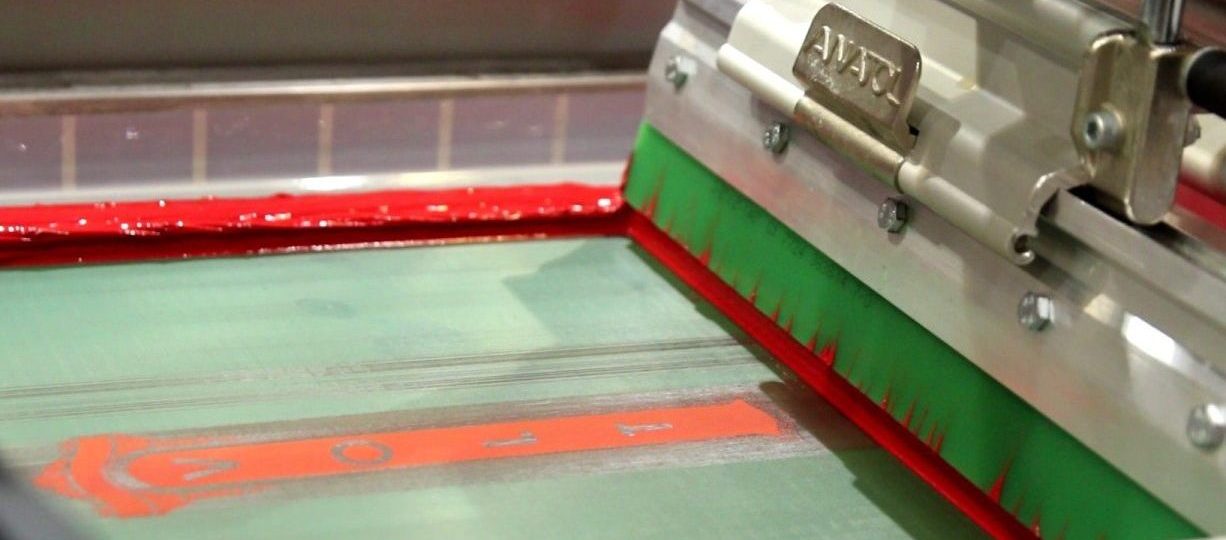

High density printing is a unique screen printing technique that creates bold, raised, and vibrant designs with a premium look. By applying thick layers of ink, it delivers long-lasting colors, tactile appeal, and eye-catching graphics. Discover how this method helps brands and designers produce unforgettable apparel with maximum visual impact.

Leer más

Discover how to boost your screen printing speed without sacrificing quality. From choosing the right equipment and inks to streamlining setup, curing, and team training, these practical tips help you achieve faster turnaround times while keeping prints sharp and professional.

Leer más

Conveyor dryers are essential for high-quality screen printing, but common mistakes can hurt results. This article covers four key issues—wrong temperature, incorrect belt speed, poor maintenance, and overloading—and offers practical solutions. Learn how Anatol’s conveyor dryers help ensure consistent curing and improved efficiency.

Leer más

Keep your screen printing machine in top shape with our maintenance guide. Learn daily, weekly, and monthly tasks to ensure high-quality prints and avoid downtime. Discover when to call Anatol’s professionals for expert repairs and maximize your equipment’s lifespan.

Leer más

Pricing is the backbone of a successful screen printing business. This guide helps you calculate true costs, set minimum orders, apply volume discounts, and build a sustainable, profitable pricing strategy.

Leer más

Many small shops start with manual screen printing, but growth brings limits. Explore 7 clear signs it’s time to upgrade to automatic presses. With Anatol Equipment’s support, streamline production, improve quality, and increase profits while keeping your shop competitive and ready for the future.

Leer más

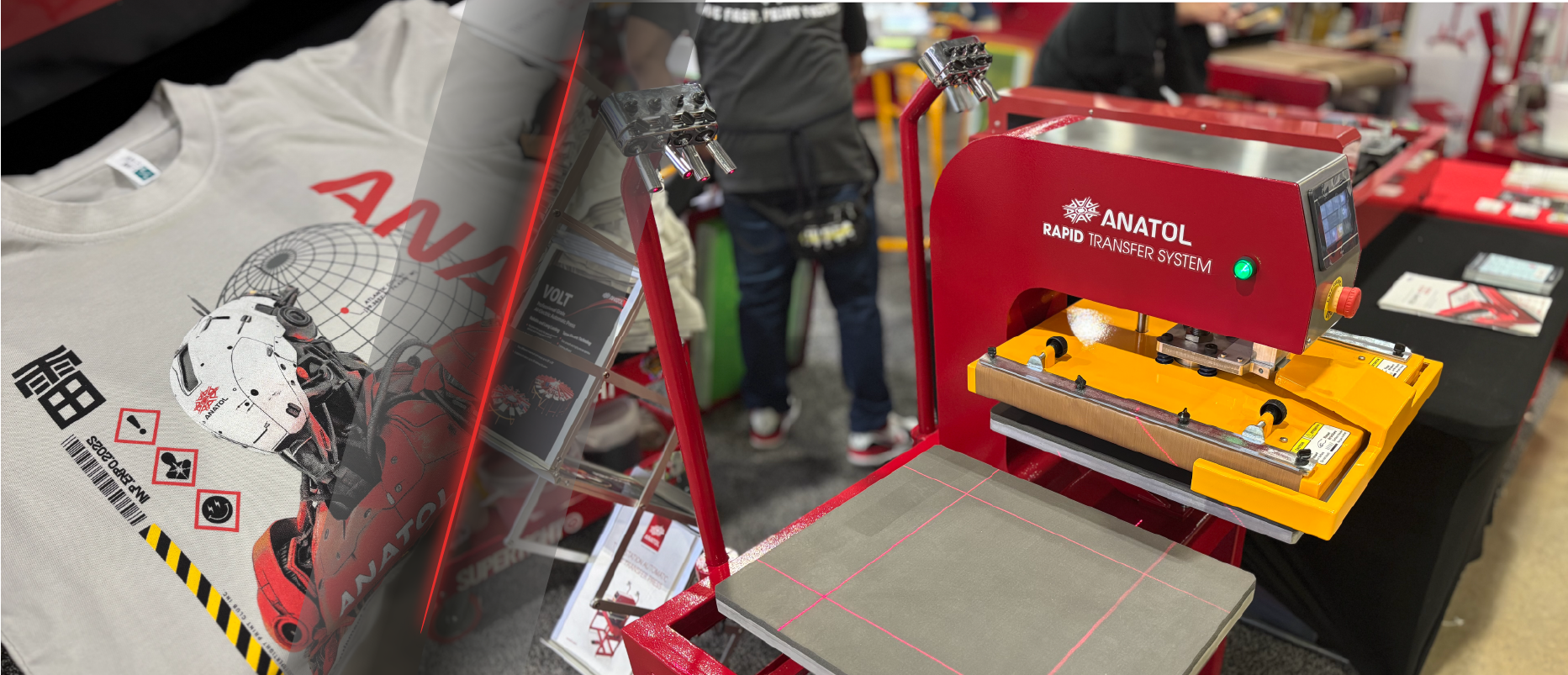

Discover how Kyle and Kim Blumenberg transformed West County Tees & Embroidery into a thriving custom merchandise business in Chesterfield, Missouri, with the Anatol VOLT automatic press. From humble beginnings with a manual press to serving schools and sports teams, their story highlights the power of quality, community, and cutting-edge equipment. Read more about their journey and the impact of the VOLT!

Leer más

Master squeegee pressure for flawless screen printing. This guide covers setting optimal pressure, avoiding common mistakes, and using Anatol’s advanced equipment for vibrant, sharp prints. Learn expert tips, adjust for inks and substrates, and boost efficiency with precise, digital controls.

Leer más

Learn how to reduce plastisol ink use in screen printing with eco-friendly alternatives like water-based, discharge, and soy-based inks. Optimize your setup with Anatol’s advanced presses to minimize waste while maintaining quality. Discover sustainable practices for vibrant, environmentally conscious prints.

Leer más

DTF vs. HTV: Which textile printing method suits your needs? Compare design complexity, fabric versatility, durability, and cost. DTF excels in vibrant, detailed prints for bulk orders, while HTV offers simplicity and unique finishes for small projects. Choose the best for your business or hobby!

Leer más

Discover all the essential supplies needed for successful heat press projects, including high-quality heat press machines, heat transfer vinyl (HTV), transfer paper, cutting tools, blank apparel, protective accessories, and design software. This comprehensive guide helps you achieve professional, vibrant custom designs right from the comfort of your home.

Leer más

Learn how to use a heat transfer press with our beginner’s guide! Create vibrant, long-lasting designs on T-shirts, hats, and more using Anatol’s user-friendly machines. Follow our step-by-step process to achieve professional results, avoid common mistakes, and start your custom apparel journey today!

Leer másYour message was successfully sent!