Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

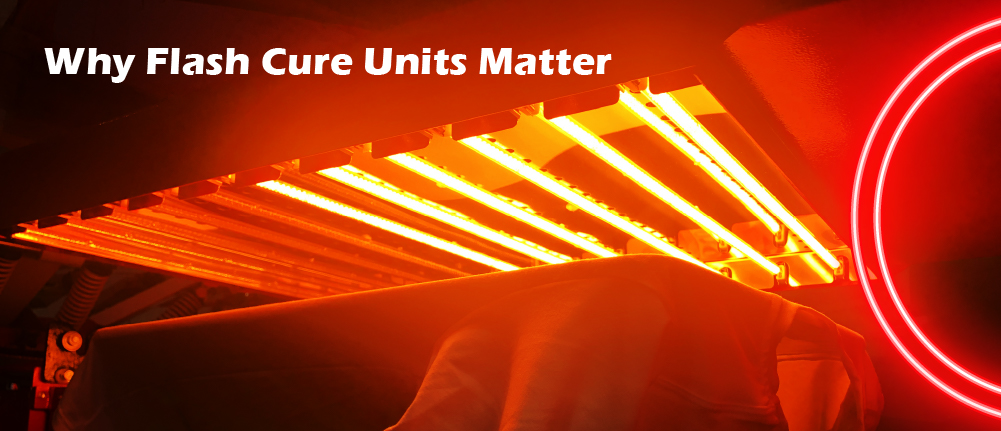

Flashing is a critical step in the screen printing process, especially when working with multi-color designs or specialty inks. It refers to the process of briefly curing the ink between print strokes using a flash dryer.

Leer más

A flash cure unit allows screen printers to optimize their screen prints. With a flash cure unit, you can overlap your colors without unintended blending or put down an underbase for a more opaque print. Getting those optimal results takes some skill with your flash cure unit, and if you don’t know the ins and outs of using a […]

Leer más

Screen printing requires heat. Every screen printer knows that applying the right amount of heat for the right amount of time results in a crisp screen print that’s fully bonded to your substrate. Sometimes, however, heat can prove the enemy.

Leer más

Flash cure units are a mainstay in nearly every screen printing shop. They’re crucial when it comes to printing a white underbase or when printing abutting or overlapping colors.

Leer más

In screen printing, safety comes first. The well-being of your press operators and other employees is often contingent upon their knowledge of and familiarity with the equipment they’re using.

Leer más

By Michael Jirasek

I remember the first time I worked with a quartz flash. It was a little scary! Flash settings can be tricky and require attention to detail. However, the payoff in increased production more than makes up for the learning curve. Here’s a general guide to help you find the right quartz flash settings for your print jobs.

Leer más

When it comes to your screen printing production, a flash cure can either be your best friend or your worst enemy – it can be a big help or it can slow you down. Understanding the different types of flash units and their appropriate uses will help you get the most out of them.

Leer másYour message was successfully sent!