Creating and drawing from a detailed library of your screen printing experiences will help you overcome future challenges. Carefully documenting the lessons you learn over the course of your screen printing career can go a long way towards helping you clear those hurdles.

Put Your Screen Printing Experience to Good Use

Recently on a screen printing forum, someone inquired about how best to print a certain multicolor job. There were several responses, each acknowledging the worthiness of the other approaches but offering some unique suggestions for how that printer would tackle the job. The value of this is that each of these printers has learned their trade, recalled previous similar situations and applied what they learned to this printer’s situation.

As a screen printer, it’s only to your benefit to follow their example – not just to help others, but to help yourself. Recording what works and what doesn’t work is critical to the development of every business. Whether you’re a one person shop or a larger business with multiple employees and machines, the importance of recording what you’ve learned and keeping up to date with the industry can’t be overstated.

Record the Right Information

Ever hear the following in your shop?

«Didn’t we just print this job? Or one just like it?»

Ever catch yourself saying:

«Anyone remember how we did it?»

Odds are you’ll spend too much time trying to recall how you handled a similar past job – time that could be spent printing!

If you carefully record the details of the job you print today, you can make life a lot easier on yourself when a similar job comes up in the future. Important specifications to record include:

- The customer’s name

- The dates the order was placed and completed

- The type and color of apparel printed

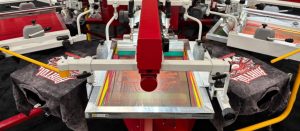

- Which press you used for the job (you might have separate forms for manual and automatic jobs)

- The number of colors

- The print head order

- The brand and color of ink (and – if needed – the recipe for mixing the ink)

- The mesh count of the screens used on the job

- The squeegee and flood bar angle and speed

- The amount of print strokes used

- Your flash cure settings

- Your conveyor dryer settings

Always leave room to enter important notes and additional information that isn’t covered in the list. It’s also helpful to include a picture or pellon of the final print for reference.

Create a System that Works for You

There are some shop management software programs that will let you record some or most of this information. These do cost some money, so some screen printing businesses create their own document for recording job details – a simple Word or Excel file will do the job.

The most important thing to consider when recording your job details is that you’ll need to be able to recall the information quickly and easily as needed. Every printer and every shop is different, so come up with a system that works best for you. When properly categorized, your catalog of knowledge will pay back in spades as your productivity increases through the application of the lessons you’ve learned as a screen printer.

Looking for more tips on handling screen printing challenges? Check out this blog:

Screen Printing Quality Control: Stop Problems Before They Start