Корзина пуста.

ru

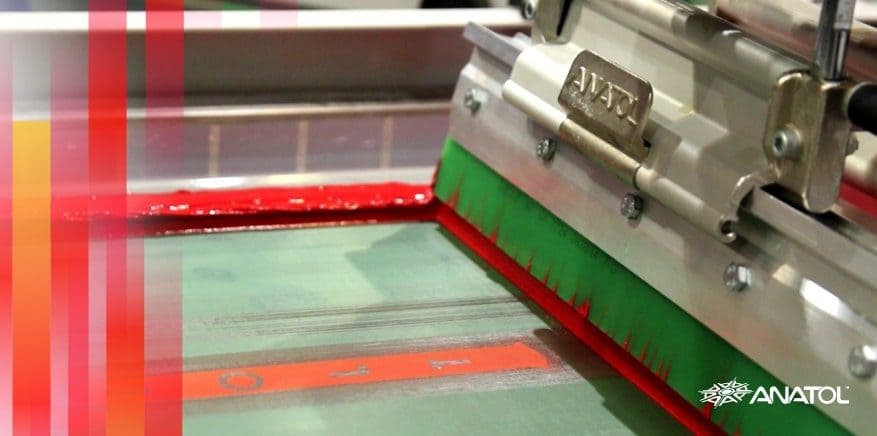

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Телефон: +1 847-367-9760

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

If you are in the market for a new screen printing press for your shop, you’ve likely discovered that there are endless options for your new machine. It can be difficult to navigate all of the different types and know what tools and features you will find most useful in your shop. Here are some of the many options — from basics to special optional features — that you will encounter as you choose the right screen printing equipment for your needs.

As you shop for a new manual or automatic screen printing machine, there are some basic decisions you will have to make to decide which is best for the job. Here are the first decisions you will have to make as you narrow down your search.

The primary decision in shopping for a new press is whether to buy a manual or an automatic screen printing machine. Most screen printers who are looking to upgrade from their existing equipment begin their shopping knowing which type they are looking for. For novice screen printers: A manual relies on a human operator to perform all of the steps of screen printing. During printing, the operator puts ink on the screen, lowers the screen to the substrate, pushes or pulls the squeegee across the screen to make the print, then raises the screen and rotates the carousel, if the machine is big enough to have one. An automatic uses electricity and/or air pressure to undertake all of those steps (except placing the ink); an operator only needs to set the job parameters and load and unload garments. Manual machines are popular for new printers, and even larger shops will keep a manual on hand for small runs, specialty prints or samples. Printers generally will upgrade to an automatic when demand is outpacing the speed at which they can lay down manual prints, or when the quantity of printing is too physically difficult to undertake on a manual.

How many colors do you need your new machine to be able to print? The number of print heads will determine how many colors you will be able to print for each job. If you are new to screen printing, the number of colors that can be printed will typically be the second number in the description — for example, an Anatol VOLT 6/4 has 6 stations and 4 print heads (the remaining two stations are for loading and unloading). This may be reversed in the description for manual machines; an Anatol Thunder 6/4 can hold 6 screens and has 4 pallets.

To determine how many colors you need for your shop, it can be helpful to look at your most recent jobs. What is the maximum amount of colors you’ve printed? Have you had to turn down jobs because you were limited by the current size of your machine? You will want to choose a model that offers enough screens to meet the color demand of your designs. Many screen printers will go beyond that and choose to add an extra print head or two to accommodate future growth and demand, and some will purchase a machine with as many heads as their budget and shop space will allow. As you select the number of colors for your new screen printing press, remember that if you print a white underbase on dark shirts, that will take up one print head, as will a flash cure and any cool down stations you plan to use.

In addition to number of colors, you will need to choose how many print stations your press has. Automatic machines have more stations than print heads so you have a place to load and unload shirts on the pallets without a print head getting in the way. Some automatics have a single station for both loading and unloading; this is a good option if your machine will be run by a single operator. If you plan on having multiple people run it, a machine with dedicated load and unload stations can help speed up your production. Anatol automatics are also available with a «Heads Up» option — a print head on a hinge — that allows you to raise the last head out of the way to create an unload station as needed.

Automatic presses like Anatol’s can accommodate a wide variety of screen sizes. The size screens you choose may depend on your existing demand, but you should also consider future growth and desired printing capabilities. Larger screens can allow you to create oversize prints or print on larger items, such as blankets, towels or long pant legs.

If you choose to purchase an automatic screen printing machine, you will have one more important choice to make: Will you buy a pneumatic or an all-electric press? Traditionally, screen printing machines have been pneumatically-powered, relying on air pressure to raise and lower the squeegee and floor bars, rotate and lift the carousel, and move the print carriage back and forth. Powering pneumatic machines means adding an adequate air compressor to your shop. Another option for an automatic is to go all-electric, removing air power from the equation altogether. Electric machines like the Anatol VOLT are powered completely with electricity, eliminating the need for an air compressor. These are an excellent option for screen printers who don’t have room in their shops for a large air compressor and for screen printers who don’t want the noise of a compressor in their shops. In addition, electric machines are better able to maintain print consistency over time, as they rely on precise electric motors for movement instead of air pressure which can fluctuate.

Once you narrow down the type and size of screen printing press you want to purchase, you will find a host of special features you can add. Some of the helpful options you can select on Anatol equipment include:

One of the most popular special features for manual machines is the all-heads-down feature. All-heads-down allows the individual screen holders to be lowered at the same time. This can allow multiple operators to print at the same time, which can help you fill orders more quickly or enable you to print multiple jobs on the machine at the same time.

Anatol machines offer several different configuations of screen clamps. Anatol offers side screen clamps as a standard feature on our automatic presses, but on most models you can also choose front/rear clamps instead. Anatol’s mechanical Speed Clamps apply consistent pressure to the screens to hold them firmly in place, ensuring tight registration. For printers who desire pneumatic screen clamps, you can add this feature to many models of Anatol machines.

On an Anatol automatic press, you can choose to add the heads-up feature. This feature allows a hinged print head to be lifted up and out of the way during printing. With heads up, you essentially get two machines in one: an 8 station/7 color machine can be transformed into an 8 station/6 color machine as needed. This can be valuable in speeding up production: Two operators can be working on the same print job, with one operator loading shirts, and the other lifting the last print head to create a dedicated station for unloading.

On Anatol automatic presses, a foot pedal can be added to operate the automatic indexer. This allows the operator to rotate the carousel and tailor the speed of production to his or her capabilities. A foot pedal can help prevent misprints and other errors as it lets the operator set a comfortable working pace and not struggle to keep up with the speed of the machine.

A laser alignment system allows you to accurately set up and load your press for easier and more accurate registration and printing. A laser alignment system allows you to verify that all pallets are placed in the same location on the pallet arms. The lasers also can be set up to create guides on the pallets for accurate garment loading and print placement, eliminating the need for physically marking pallets and creating guide marks that are still visible even after the shirt is loaded.

Proper registration during set up is crucial to clean, accurate screen printing. Anatol’s Registration Made Easy (ARME) system is designed to make registration faster, easier and more accurate. A master frame and grid sheet allows printers to align film positives to screens on exposure units so printers know the artwork placement is uniform on every screen. A guide pallet mounted on the machine provides registration points for accurate on-press registration.

Advanced automatic screen printing presses feature digital controls that allow you to quickly and accurately set your printing parameters. You can take this feature one step further with individual print head controls. When your machine has individual print head controls, you have the main control panel, and each individual head has its own control system that allows you to adjust settings like print and flood speed and off-contact distance, indexer locking and unlocking, as well as enabling easy test printing. Individual print head controls give you unparalleled control over your press and can save you time setting up jobs.

Screen printing presses are large and bulky, which can make them difficult to fit through narrow doorways for installation or to move once they are in place. Anatol’s automatics are available with optional disassembled bases for easier installation and relocation. Depending on the size of the press, an Anatol automatic machine can fit through a doorway as narrow as 28 inches with the disassembled base option.

A screen printing press is a major investment, and you want to choose the right model for your shop. The wide variety of available options allows you to find a machine that fits your needs, but all of those options also can make shopping overwhelming. To determine which options are right for your shop, consider talking to other printers or visiting other print shops to see different machines and features in action, look at the demands of your shop’s customers, consider what you would like to be able to do on your new press that you can’t do now, visit trade shows and talk to representatives from equipment manufacturers or experienced distributors.

Looking for some more information on choosing the best machine for your needs? Check out these blogs:

Getting Started with Your First Manual Screen Printing Press

A Beginner’s Guide to Buying an Automatic Screen Printing Press

Your message was successfully sent!