Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Revolucionando la industria de la serigrafía a través de tecnología de punta y servicio de calidad

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Are you passionate about screen printing? Do you dream of turning this hobby into a profitable business? Screen printing offers numerous opportunities for creative entrepreneurs. If you love working with designs, this business could be a great fit for you. It also offers plenty of opportunities to grow and take your venture to the next level.

Starting a screen printing business has a lot of benefits. It’s a great option for entrepreneurs because it’s flexible, cost-effective, and has high demand. Plus, you can get creative while building a profitable business:

Screen printing is a popular method known for producing vibrant and durable images. It’s an excellent choice for projects that need high-quality, long-lasting results. It works on a variety of materials, making it a versatile choice for many projects. This method is commonly used in many industries. It’s perfect for mass-producing clothing, promotional items, and signage. Its efficiency makes it a go-to choice for large orders.

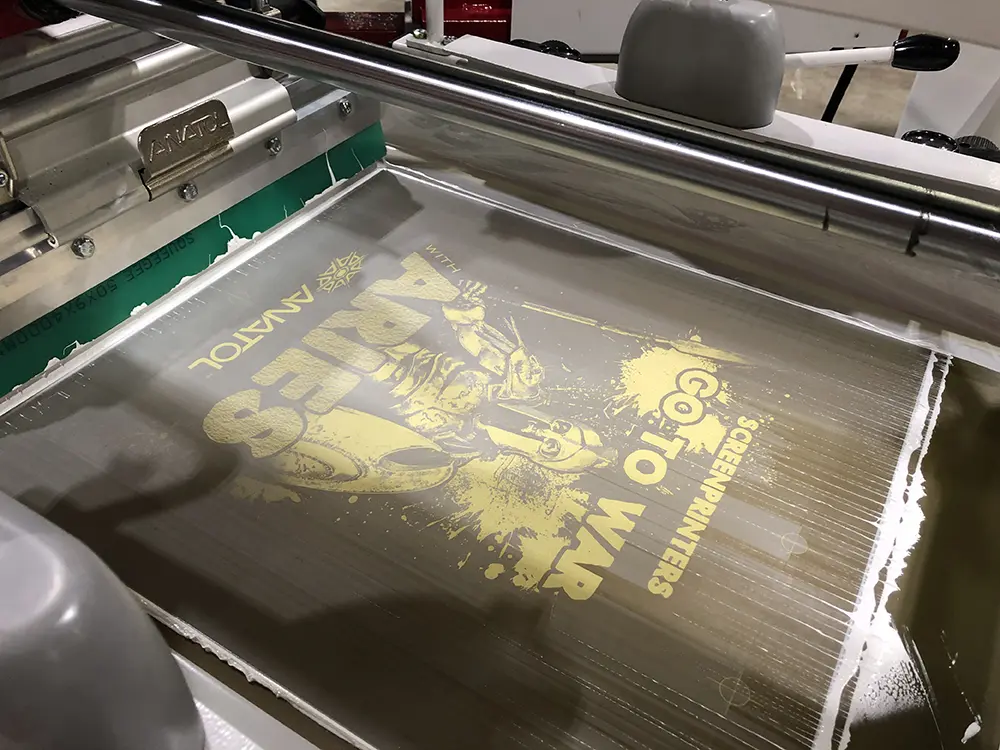

Screen printing works by transferring an image onto a surface using a stencil. The stencil is placed on a mesh screen, and ink is pushed through it to create the design. It’s a simple but effective process for making detailed prints. Ink passes through the open areas of the mesh, creating an accurate print on the material. The technique allows printing on various surfaces, including textiles, plastic, metal, and wood.

The screen printing process involves several key steps:

Screen printing comes with a few standout benefits. That’s why so many businesses and brands prefer it. It’s reliable, versatile, and ideal for producing high-quality prints.

One of the key benefits of screen printing is its durability. The prints hold up well, even after many washes and constant use. This makes it perfect for clothing or other items that need to last a long time.

Screen printing delivers bright, vibrant colors, ensuring the designs stand out. This is really important when it comes to branded clothing. The colors need to be spot on to keep the brand’s identity strong and consistent. Without accurate colors, the brand might lose its recognizable look.

Screen printing is highly cost-effective, especially for large production runs. Once you’ve made the stencil, you can use it over and over again. Whether it’s for hundreds or even thousands of items, this reuse helps bring the cost per item way down. This makes it an ideal solution for bulk orders.

Choosing the right equipment is key to the success of your screen printing business. It directly impacts the quality of your prints and overall efficiency. Below are the essential tools you’ll need to get started:

Here’s a step-by-step guide to help you get started with screen printing:

1. Choose the Right Fabric

Most screen printers use cotton or polyester fabrics. These materials work well with the inks that are commonly used in screen printing.

2. Prepare the Design

Create your design and print it on transparent film. This design will be used to expose the emulsion-coated screen.

3. Transfer the Design to the Screen

Expose your screen to UV light with the design in place to create a stencil on the mesh.

4. Apply the Ink

Position the screen over the fabric and use a squeegee to apply an even layer of ink. For multi-color designs, you’ll need separate screens for each color.

5. Cure the Ink

Dry the ink using a Flash Cure Unit or a conveyor dryer if you are printing in one color. Ensure that the ink is properly cured to prevent fading or cracking.

Modern screen printing has become an automated process. This process allows businesses to produce large batches of products quickly and efficiently.. Automated machines can handle high volumes, delivering consistent quality while reducing production time.

Screen printing is used across various industries, including:

Automated screen printing machines have a lot of key advantages. They can make your business run more smoothly by speeding up production and reducing manual work. Plus, they help you keep things efficient and consistent:

Screen printing is one of the best tools for getting clean, sharp prints on a variety of surfaces. It works great for different materials, giving you high-quality results every time. This technique guarantees brilliant colors and long-lasting durability. Whether you’re doing a large print run or just a small one, everything will stay perfectly in place. You can count on high-quality results every time

Below are a few additional tips to keep the screen printing business going strong:

Buy the best printing equipment to ensure great results. Choosing presses that are reliable and built to last is essential. This helps maintain the quality of your prints, even as time goes on and your equipment gets more use. Anatol presses are well worth the investment.

Grow with the business at your own pace. You can start small with a simple manual press and expand as you go. It’s an easy way to get started. However, be sure to train your team properly—accuracy during setup is key. If the prep work isn’t done right, it can affect the quality of your prints.

Focus on the process. Take the time to learn as much as you can about screen printing techniques and equipment. The more knowledge you have, the better your results will be. It’s worth investing the effort to master the process. The more you know, the better you’ll get, and soon you’ll become a real pro at it.

All you need is the right equipment, some solid knowledge, and a bit of dedication. With that, you can easily turn your screen printing business into a successful and profitable venture. It’s all about putting the right pieces in place! It just takes the right tools and commitment to make it happen.

Your message was successfully sent!