Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

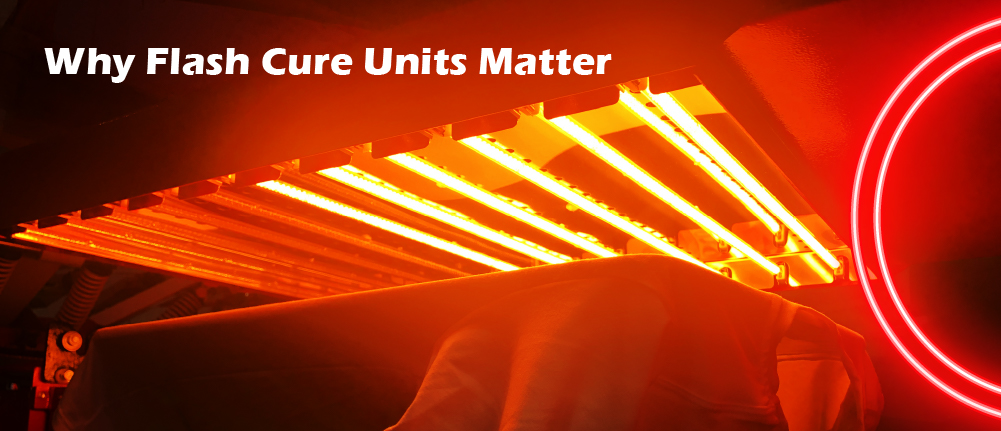

Flashing is a critical step in the screen printing process, especially when working with multi-color designs or specialty inks. It refers to the process of briefly curing the ink between print strokes using a flash dryer. By applying heat for a short period, the ink surface is partially dried, creating a tack-free layer that prevents smudging and ensures sharp registration for subsequent colors.

One of the main roles of flashing is to maintain print clarity in multi-layer designs. Without flashing, wet inks can easily mix, bleed, or cause misalignment when additional colors are applied. A properly flashed layer locks the first color in place, allowing printers to add new layers on top without compromising detail or vibrancy.

Flashing also plays a key role when printing on dark garments. Often, a white or light underbase is printed first to create a solid foundation for the colors to sit on. Flashing this underbase ensures that the top colors appear brighter, more consistent, and closer to the intended design.

In addition, flashing is essential for specialty inks such as puff, metallic, or high-density inks. These inks often require a partial cure between layers to achieve the desired texture and finish.

Modern flash cure units significantly enhance what’s possible in screen printing. Advanced models offer features like built-in timers, temperature sensors, and multi-zone heat control that help ensure uniform and reliable curing. Such precision helps to avoid both under-flashing (which can leave ink surface too wet) and over-flashing (which can over-cure and prevent proper bonding of subsequent layers).

When it comes to industry-leading flash cure equipment, Anatol stands out. The company produces a range of flash cure units tailored to different shop sizes and needs. Here are some ways Anatol’s units elevate the flashing process:

To make full use of flashing (especially with high-quality equipment like Anatol’s):

Flashing is more than just a “pause” between print colors; it is a decisive step that shapes the final quality of screen printed garments. When paired with advanced equipment such as Anatol’s flash cure units, flashing becomes a precision tool — delivering sharper colors, better registration, improved specialty effects, less waste, and higher throughput. For any shop serious about quality, investing in good flash-cure capabilities is indispensable.

Your message was successfully sent!