Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

Революция в индустрии трафаретной печати благодаря передовым технологиям и качественному обслуживанию

Anatol Equipment Manufacturing Co.

1429 S Shields Dr

Waukegan, IL 60085

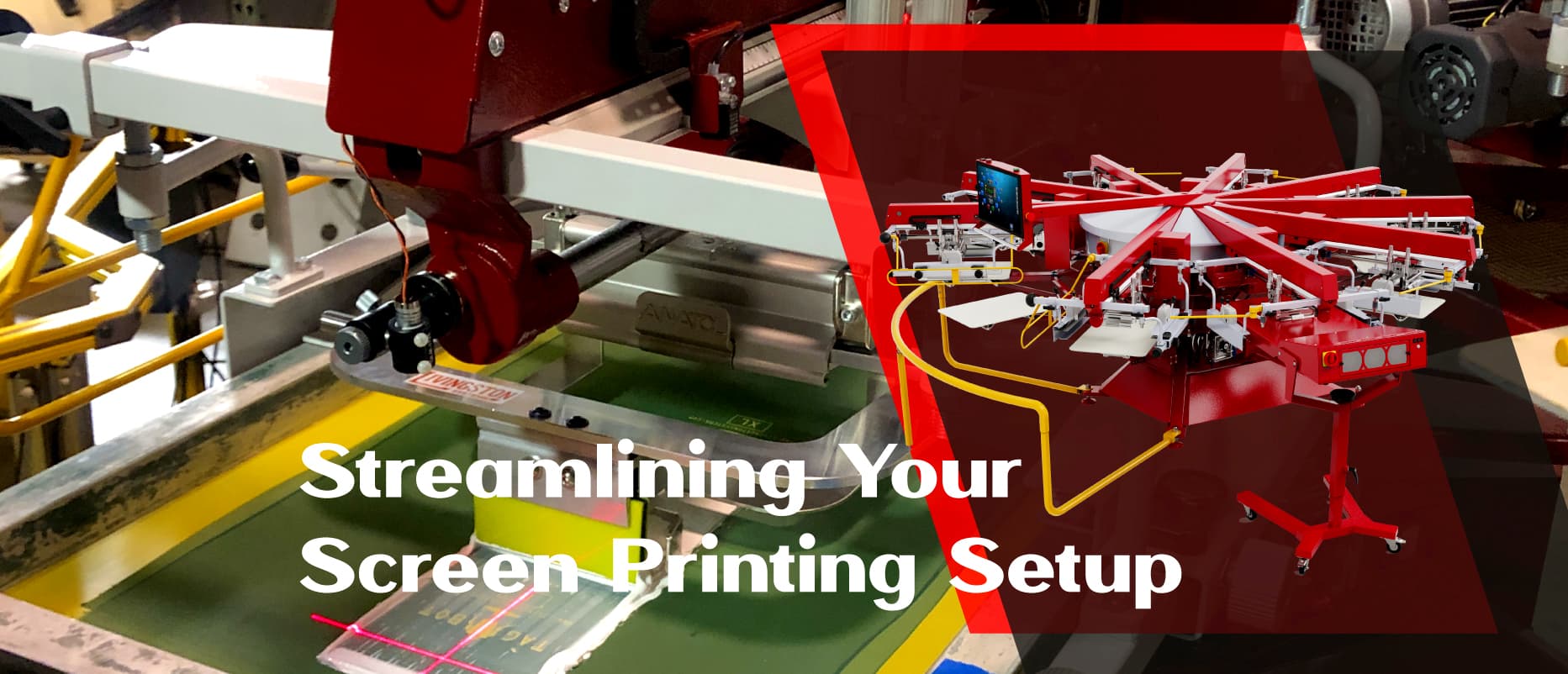

For any screen printing shop, the darkroom is the backbone of efficient production. Mastering screen printing darkroom optimization ensures your printing processes run smoothly, delivering top-tier print quality while saving time. At Anatol, we know how important it is to determine the right number of screens your shop needs to balance efficiency and cost.

This guide provides tips on improving screen printing efficiency and best practices for screen reclamation. It helps you fine-tune your darkroom setup, with a special focus on shops using automatic systems like the Anatol VOLT.

A well-organized darkroom minimizes bottlenecks, enhances print quality, and supports high-volume screen printing solutions. Handling water-based inks or plastisol? The number of screens you use and the efficiency of your reclaiming process can significantly impact your workflow. Here’s how to ensure your screen printing products shine with a properly optimized darkroom.

Pro Tip: The all-electric, compressor-free Anatol VOLT press reduces downtime and enhances screen printing efficiency. Make sure your screen inventory can keep up with its high-speed performance.

Efficient darkroom setup for screen printing hinges on proper screen handling and reclamation. Here’s how to streamline:

Screen Preparation: Use high-quality ink and emulsion to coat screens evenly. Anatol’s automatic coating machines ensure consistent application, reducing defects and improving print quality.

Screen Reclamation Best Practices:

Investing in the right tools can transform your screen printing shop:

A cluttered darkroom slows production. Implement these screen printing efficiency tips:

In more than 70 countries, Anatol’s automatic screen printing equipment like the VOLT press is known for its reliability and precision. Pair it with our coating machines and ink mixers for a darkroom setup for screen printing that maximizes efficiency and minimizes waste. Our equipment supports screen reclamation best practices, ensuring your screens are always ready for the next job.

Optimizing your darkroom with the right number of screens, efficient printing processes, and automatic screen printing equipment is the key to staying competitive. By implementing screen printing darkroom optimization and screen reclamation best practices, you’ll save time, reduce costs, and deliver exceptional screen printing products.

Ready to revolutionize your shop? Click here to explore Anatol’s high-volume screen printing solutions and power up with the Anatol VOLT automatic press.

Your message was successfully sent!